Friday, May 31, 2013

AOC T942WE – T2242WE – T2442E – LCD MONITOR TV - DISASSEMBLE PROCEDURE

DISASSEMBLY

Unscrew the 4 screws to remove the STAND and BASE. T942WE/ T2442E

T2242WE

Unscrew the 10 screws to remove REAR COVER. T942WE/ T2442E

T2242WE

Disconnect the connectors; unscrew the 5 screws to remove IR

BOARD and separate MAIN FRAME and BEZEL. T942WE

T2242WE

T2442E

Unscrew the 2 screws to separate panel and main

frame.

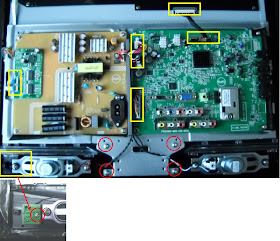

Unscrew the screws to remove MAIN BOARD and POWER BOARD. T942WE

T2242WE

T2442E

AOC T942WE – T2242WE – T2442E – LCD MONITOR TV - SERVICE MODE [FACTORY MODE] ENTRY PROCEDURE - MAIN POWER & CONVERTER BOARDS SCHEMATICS

SERVICE MODE

- Turn on the TV, press MENU key with remote control, then press number key 1 => 9 => 9 =>9.

- Service mode menu will be displayed.

- Click on "Autowhite 100%" in the PC and Component modes:

- PC mode: TIM = 107; PAT =48 Component mode: TIM = 311; PAT = 184

Take other model’s factory menu for example:

- To exit service mode, select 'Exit' on window, and press Ok [Enter]

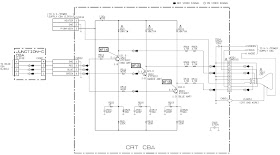

MAIN POWER - SCHEMATIC

CLICK ON PICTURES TO ENLARGE

CONVERTER BOARDS SCHEMATICS

SANYO CE29FFV2-F - TRUE FLAT COLOR TV - SERVICE MODE - ERROR CODE DISPLAY & OTHER ADJUSTMENTS DETAILS - CRT 29” Philips A68ERF012X013 CRT 29” Samsung A68QCP993X001

FACTORY SPECIAL MODE

The factory mode is a special TV working mode intended to

help in the manufacturing process and it is identified on the screen with the

message “FAC”. This mode is never suited for customer use. The main differences respect to normal mode

are:

- The standby mode is always disabled.

- The Blue-back (no sync. signal present) is disabled.

- The customer adjustments ( volume, contrast …) work faster.

- The timer off works but it does not change to Stand-by mode.

- Change of programs and TV/AV swithing faster. Cancelled mute.

- In case of finding the TV set in Factory mode, it must be taken out of this state.

- To do so, enter the clock setting menu on the customer OSD and then exit.

SERVICE MODE

- Holding down the front key “VOL-” and simultaneously pressing the teletext green key from the remote control access the service menu. The service menu is a two level structure as shown in the diagram below.

- The active keys (local or remote) in service mode are: VOL-, VOL+, P-, P+, MENU and the digits. The navigation through this menu works the same than in the user menu.

- The P+ and P- keys allow to navigate through the options in the active menu.

- The VOL+ key opens the second level menu if available. If there is a highlighted adjustment, the VOL- and VOL+ keys allow to change it.

- The MENU key goes back one level menu. If the active menu is the main one, it exits the service mode.

- The digit keys allow direct entry for adjustments.

- The SERVICE mode is exited by pressing any other key.

CLICK ON PICTURES TO MAGNIFY

FACTORY DEFAULT DATA VALUES

SWITCH-ON SEQUENCE

In case of malfunction it is very important to know the

switch-on procedure:- When the reset is at low level the microprocessor begins to work.

- It recalls from NVM the last state before the switch-off.

- If it is STAND BY, it remains in STAND BY. If it is ON, it continues the switch-on procedure.

- It waits until a falling edge in the 16/9&BSYNC signal occurs.

- The port B_HIGH is set (B_HIGH oscillating).

- It waits until a rising edge in the 16/9&BSYNC signal occurs.

- It reads the CTL1 signal. If this signal doesn’t rise before 160mS the process is stopped indicating ERROR_4.

- The Video processor is started via I2C bus. If there isn’t any answer the process is stopped indicating ERROR_1.

- There is a 1 second delay.

- The deflections start. If there are failures the process is stopped indicating ERROR_2 or ERROR_3.

- It waits until the cathode heater is warm by inspection of the video processor register bit AKB.

- The picture and the sound are switched on and the procedure is finished.

PROTECT MODE & FAILURE INDICATIONS [ERROR CODES]

The microprocessor checks periodically the different parts

of the circuit and if it detects any fault in a safety defined part then it

puts the TV set in PROTECTED mode. The red LED indicates the found error code. The red indicator lamp flashes every 0,3

seconds and stops during 0,7 seconds. The number of flashes depends on the

error code.

The 1, 2, 5 and 6 error codes are read via the I2C Bus.

The 3 and 4 error codes are read through the CTL1, CTL2 and

-PD&FAIL signals.

In all cases except ERROR_5 the power supply is set in

SMPS_B_LOW state.

Protect mode inhibition

- In order to facilitate the TV set repair it is possible to disable the protect mode. By pushing the M key (PL100) in a fault detection situation, the microprocessor resumes normal execution flow except in ERROR_4 state (Power Supply Short-circuit). In this case the microprocessor keeps the power supply in MPS_B_LOW state (the M key does not act).

- When it is necessary to replace the IC800, it is strongly recommended to replace also the current sensor resistors R804 and R805 (they may be also damaged or altered).

- Keep in mind that when the power supply is forced to SMPS_B_HIGH state and without current consumption at the main output (deflection stopped), B6 is the stabilized output. The minimum voltage circuit is working and B6 can go down from the nominal 10 volts to 7,5 volts approximately. Also, in this situation B1 goes up until 160 - 180 volts in TV sets with 110º CRT.

- When the TV set starts up, the microprocessor checks the non-volatile memory in order to know if it has been initialized. Even if it detects no initialization it will continue the start up procedure with a minimum default adjustment values stored in ROM. Then, in case of NVM replacement, it is necessary to initialize the non-volatile memory from the SERVICE menu (it will load a complete set of default values) and afterwards adjust all the controls to its correct value.

TOKAI LT-VHS36 - T6608FJ [CHINA] - SCHEMATIC DIAGRAMS - POWER SMPS USING 2SK2647 FET AS POWER SWITCHING, H/V SCAN OUTPUT - CRT BASE CARD SCHEMATIC & MECHANICAL ALIGNMENTS TO VCR

POWER SUPPLY SCHEMATIC

CRT BASE CARD CBA SCHEMATIC

{Click on pictures to Magnify}

MECHANICAL ALIGNMENTS- Disconnect the AC plug.

- Remove the Top Case and Front Assembly.

- Insert a cassette tape. Though the tape will not be automatically loaded, make sure that the cassette tape is all the way in at the inlet of the Cassette Holder. To confirm this, lightly push the cassette tape further in and see if the tape comes back out, by a spring motion, just as much as you have pushed in.

- Turn the LDG Belt in the appropriate direction shown in Fig for a minute or two to complete this task.

- Disconnect the AC plug.

- Remove the Top Case and Front Assembly.

- Make sure that the Moving guide preparations are in the Eject Position.

- Turn the LDG Belt in the appropriate direction shown in Fig until the Moving guide preparations come to the Eject Position. Stop turning when the preparations begin clicking or cannot be moved further. However, the tape will be left wound around the cylinder.

- Turn the LDG Belt in the appropriate direction continuously, and the cassette tape will be ejected. Allow a minute or two to complete this task.

- If the tape path is unstable during reversing, the tape will be damaged.

- Note: Do not use an Alignment Tape for this procedure. If the unit is not correctly aligned, the tape may be damaged.

- Insert a black cassette tape into the tray and set the unit to REV. Then confirm if the tape has been curled up or bent at the Take-up Guide Post[4] or REV Post[5].

- When the tape has been curled up or bent, turn the alignment screw to adjust the height of REV Post.

TOKAI LT VHS-36 - T6608FJ - TV-VCR COMBO - SERVICE MODE - OPTION CODE SETUP - UNIVERSAL REMOTE SETUP CODES

TO ENTER SERVICE MODE

After replacing the IC202 (Memory) or Main CBA, the set

value in IC202 (Memory) will be lost. So it is necessary to set up or adjust in

the Service mode after its replacement.

- Turn the power on. (Use main power on the TV unit.)

- Press [STANDBY/ON], [2], [7], [1], and [MUTE] but-tons on the remote control unit in that order within 5 seconds.

- To cancel / [EXIT] the service mode, press [STANDBY/ON] button on the remote control.

- Enter the Service mode.

- Press the [STATUS] button on the remote control unit. The option code appears on the display.

- If needed, input the option code (0129) using number buttons on the remote control unit.

- To reset the software, press [PAUSE] and [5] buttons on the remote control unit. The option code is changed.

Purpose: To obtain correct operation.

Symptom of Maladjustment: The picture is dark and unit does not operate correctly.

- Connect the unit to AC Power Outlet. (exact AC230V)

- Input a color bar signal from RF (or Ext.) input and leave it for at least 20 minutes.

- Connect DC Volt Meter to TP503(+B) and TP504(GND).

- Adjust VR601 so that the voltage of TP503(+B) becomes +105±0.5V DC

Purpose: To adjust the beam current of R, G, B, and screen voltage.

Symptom of Maladjustment: White color may be reddish, greenish or bluish.

Screen Control (FBT) --- H.V./Power Supply CBA FBT= Fly Back Transformer

- Degauss the CRT and allow CRT to operate for 20 minutes before starting the alignment.

- Set the screen control to minimum position. Input the Black raster signal from RF (or Ext.) input.

- Enter the service mode. Dimmed horizontal line appears on the CRT.

- To enter the C/D/S mode, press the [VOL-] button on the remote control unit.

- To enter the CUT OFF (R) mode, press [1] button on the remote control unit.

- Turn the screen control up until dimmed horizontal line appears.

WHITE BALANCE ADJUSTMENT

Purpose: To mix red, green and blue beams correctly for pure white.

Symptom of Maladjustment: White becomes bluish or reddish.

Note: Confirm that Cut Off Adj. is correct after this adjustment, and attempt Cut Off Adj. if needed.

- Operate the unit more than 20 minutes.

- Face the unit to east. Degauss the CRT using Degaussing Coil.

- Input the White Raster (APL 100%).

- Set the color analyzer to the CHROMA mode and after zero point calibration, bring the optical receptor to the center on the tube surface (CRT).

- Enter the Service mode. Press [VOL-] button on the remote control.

- Press [4] button on the remote control unit for Red adjustment. Press [5] button on the remote control unit for Blue adjustment.

- In each color mode, Press [PROG+/PROG-] buttons to adjust the values of color.

- Adjusting Red and Blue color so that the temperature becomes 8500K (x : 290 / y : 300) ±3%.

- At this time, Re-check that Horizontal line is white. If not, Re-adjust Cut-off Adjustment until the Horizontal Line becomes pure white.

- Turn off and on again to return to normal mode. Receive APL 100% white signal and Check Chroma temperatures become 8500K (x : 290 / y : 300) ±3%.

Thursday, May 30, 2013

HYUNDAI HLT-1751 - HLT-2051 - LCD TV - SERVICE MODE [FACTORY MODE] - SOFTWARE UPGRADE METHOD & Troubleshooting Chart

HYUNDAI HLT-1751_HYUNDAI HLT-2051 _ Service Mode _ Troubleshooting _ Universal Remote Control Set-up Codes

FACTORY MODE [SERVICE MODE]

* Push MUTE-MENU-OK-SLEEP key in turn at the interval of 1 second.

MAIN ADJUSTMENTS* Push MUTE-MENU-OK-SLEEP key in turn at the interval of 1 second.

IF adjustment

* Input DV 5V into TP2, input 12V to TP6, Input 5V to TP4 and input 0V to TP5, monitor voltage of TP3, input 38.9 MHz signal to TP1, and use a non-inductance screw driver to adjust IFT L207 so that TP3 voltage is 1.65V

* Input DC 5V into TP2, input 12V to TP6, Input 0V to TP4 and input 5V to TP5, monitor voltage of TP3, input 33.9 MHz signal to TP1, adjust potential meter RP202 to set TP3 voltage to 1.65V.

* Connect IF line of tuner, control line L and L’: three disconnected points in total.

AGC Adjustment

* Receive D-8 signal of 60 db, measure the voltage of positive pole of D201 with DC potential meter.

* Adjust potential meter RP201 to make reading of potential meter just decrease below 4.0V.Input 100db from antenna, the picture should not appear non-synchronized and distorted, input weak signal of 35 dB--40 dB, color should not disappear, picture synchronizes, normal sound.

SOFTWARE UPGRADE PROCEDURE* Receive D-8 signal of 60 db, measure the voltage of positive pole of D201 with DC potential meter.

* Adjust potential meter RP201 to make reading of potential meter just decrease below 4.0V.Input 100db from antenna, the picture should not appear non-synchronized and distorted, input weak signal of 35 dB--40 dB, color should not disappear, picture synchronizes, normal sound.

* Select a serial connection wire and a VGA connection wire and then connect them by means of a patch panel

* Use a serial wire to connect the PC to the patch panel and set TV set to off state

* Open the software upgrade file holder and double click FlashUpgraderNT(use under window 2000/XP/NT)

FlashUpgrader (use under window 98), the following interfaces will show up after running the program:

Based on the computer features, set up the serial port(COM

Port). Select corresponding serial port (if it’s unable to FLASH WRITE, change

to another port). Baud is selected to be 115200. Then select Reset Target After

Download. Click FLASH push button, it’s ready to run.

Switch on TV set the FLASH write program begins to run;

After FLASH write is over, push button “cancel”

will become flash. Then shut the main power supply and its OK just switch it on

again. Do not shut the power off or

turn the TV set on during the FLASH write. Otherwise it may lead to no way for

flash to rewrite.

TROUBLESHOOTING [NO PICTURE]

Click on tables to Magnify

NO SOUND

NO PICTURE; HAVE RASTER [SCREEN]

Universal Remote Control Set-up Codes to check with Hyundai TVs [For CRT & LCD types]

0025 0031 0101 0194 0658 0673 0680 0697 0758 0777 0791 0798