Thursday, October 31, 2013

PHILIPS QFU2,2E LA CHASIS LCD TVs [PFL Seires] - ERROR CODE OVERVIEW - DETAILS

ERROR CODE OVERVIEW

CLICK ON THE TABLE TO ZOOM IN

Error Codes Details

Error 13 (I2C bus M3, SSB + SRF bus blocked). Current situation: when this error occurs, the TV

can reboot due to the blocked bus. The best way for further diagnosis here, is

to check the logging output.

Error 14 (I2C bus M2, BE bus blocked). Current situation: when this error occurs. The best way for

further diagnosis here is to check the logging output.

Error 15 (Fusion doesn’t boot). Indicates that the main

processor was not able to read his boot script. This error will point to a

hardware problem around the Fusion (supplies not OK, Fusion device completely

dead, link between Mips and Stand-by Processor broken, etc...)

Other root causes for this error can be due to hardware

problems regarding the DDR’s and the boot script reading from the Fusion

device.

Error 16 (12V). This voltage is made in the power supply and

results in protection (LAYER 1 error = 3) in case of absence. When SDM

(maintain grounding continuously) is activated we see blinking LED LAYER 2

error = 16.

Error 17 (Display Supply). Here the status of the “Power OK”

is checked by software, no protection will occur during failure of the display

supply, only error logging. LED blinking of LAYER 1 error = 3 in CSM, in SDM

this gives LAYER 2 error = 17.

Error 18(I2C bus M1, FE bus blocked). Current situation: when this error occurs. The best way for further diagnosis here, is to check the logging output.

Error 23 (HDMI mux). When there is no I2C communication

towards the HDMI mux after start-up, LAYER 2 error = 23 will be logged and

displayed via the blinking LED procedure if SDM is switched on.

Error 24 (I2C switch). When there is no I2C communication

towards the I2C switch, LAYER 2 error = 24 will be logged and displayed via the

blinking LED procedure when SDM is switched on.

Error 27 (Channel dec DVB-T2). When there is no I2C

communication towards the DVB-T channel decoder, LAYER 2 error = 27 will be

logged and displayed via the blinking LED procedure if SDM is switched on.

Error 28(Channel dec DVB-S2). When there is no I2C

communication towards the DVB-S channel decoder, LAYER 2 error = 28 will be

logged and displayed via the blinking LED procedure if SDM is switched on.

Error 31 (Lnb controller). When there is no I2C

communication towards this device, LAYER 2 error = 31 will be logged and

displayed via the blinking LED procedure if SDM is activated.

Error 34 (Tuner). When there is no I2C communication towards

the tuner during start-up, LAYER 2 error = 34 will be logged and displayed via

the blinking LED procedure when SDM is switched on.

Error 35 (main NVM). When there is no I2C communication

towards the main NVM during start-up, LAYER 2 error = 35 will be displayed via

the blinking LED procedure when SDM is switched “on”. All service modes (CSM,

SAM and SDM) are accessible during this failure,

observed in the Uart logging as follows: "<< ERRO

>>> PFPOW_.C: First Error (id19,Layer_1= 2 Layer_= 35)".

Error 36 (Tuner DVB-S). When there is no I2C communication

towards the DVB-S tuner during start-up, LAYER 2 error = 36 will be logged and

displayed via the blinking LED procedure when SDM is switched “on”.

Error 37 (Class-D). When there is no I2C communication

towards the Class-D amplifier during start-up, LAYER 2 error = 37 will be

logged and displayed via the blinking LED procedure when SDM is switched “on”.

Error 38(FPGA ScanBacklight). When there is no I2C

communication towards this FPGA device during start-up, LAYER 2 error = 38 will

be logged and displayed via the blinking LED procedure when SDM is switched

“on”. This device supports the backlight + boost pwm control,

scanning, 3D drive and ambilight buffering.

Error 42 (Temp sensor). Only applicable for TV sets

equipped/stuffed with temperature devices.

Error 43 (Light sensor). When there is no I2C communication

towards the light sensor device during start-up, LAYER 2 error = 43 will be

logged and displayed via the blinking LED procedure when SDM is switched “on”.

Error 44 (Touch control). When there is no I2C communication

towards the touch control micro processor during start-up, LAYER 2 error = 44

will be logged and displayed via the blinking LED procedure when SDM is

switched “on”.

Error 46 (RF4CE). When there is no I2C communication towards

the RF4CE driver during start-up, LAYER 2 error = 46 will be logged and displayed

via the blinking LED procedure when SDM is switched “on”.

Error 53. This error will indicate that the Fusion device

has read his boot script (when this would have failed, error 15 would blink)

but initialization was never completed because of hardware problems (NAND

flash, DDR...) or software initialization problems. Possible cause could be

that there is no valid software loaded (try to upgrade to the latest main

software version). Note that it can take a few minutes before the TV starts blinking LAYER 1 error = 2 or in SDM

(maintain grounding continuously), LAYER 2 error = 53.

To get more details, check the previous post here.

SERVICE MODE & ERROR CODES - LED BLINKING CODES - PHILIPS PFL-SERIES LCD TVs

SERVICE ALIGNMENT MODE [SAM]

To

perform (software) alignments.

To

change option settings.

To

easily identify the used software version.

To

view operation hours.

To

display (or clear) the error code buffer.

To

Activate SAM

Via

a standard RC transmitter: Key in the code “062596” directly followed by the

“INFO” or “OK” button. After activating SAM with this method a service warning

will appear on the screen, continue by pressing the “OK” button on the remote control.

Contents

of SAM

Hardware

Info.

[A].

SW Version. Displays the software version of the main

software (example:QF1XX-1.2.3.4 =

AAABB_X.Y.W.Z).

AAA=

the chassis name.

BB=

Product ID.

X.Y.W.Z=

the software version, where X is the main version number (different numbers are

not compatible with one another) and Y.W.Z is the sub version number (a higher

number is always compatible with a lower number).

[B].

Standby processor version. Displays the software version of the standby

processor.

[C]. Production Code.

Displays the production code of the TV, this is the serial number as printed on

the back of the TV set. Note that if an NVM is replaced or is initialized after

corruption, this production code has to be re-written to NVM. The update can be

done via the NVM editor available in SAM.

Operation hours. Displays

the accumulated total of operation hours (not the standby hours). Every time

the TV is switched “on/off”, 0.5 hours is added to this number. Errors

(followed by maximum 10 errors). The most recent error is displayed at the

upper left.

Reset

Error Buffer. When “cursor right” (or “OK” button) pressed here, followed by

the “OK” button, the error buffer is reset.

Alignments.

This will activate the “ALIGNMENTS” submenu.

Options

numbers. Extra features for Service. For more info regarding option codes. Note that if the option code numbers are

changed, these

have

to be confirmed with pressing the “OK” button before the options are stored,

otherwise changes will be lost.

Initialize

NVM.The moment the processor recognizes a corrupted NVM, the “initialize NVM”

line will be highlighted. Now, two

things can be done (dependent of the service instructions at that moment): Save the content of the NVM via ComPair for

development analysis, before initializing. This will give the Service

department an extra possibility for diagnosis (e.g. when Development asks for

this).

Initialize

the NVM. Note: When the NVM is

corrupted, or replaced, there is a high possibility that no picture appears

because the display code is not correct. So, before initializing the NVM via the

SAM, a picture is necessary and therefore the correct display option has to be

entered.

To

adapt this option, it’s advised to use compare, or a method via a standard RC

(described below). Changing the display

option via a standard RC: Key in the code “062598” directly followed by the

“MENU” (or "HOME") button and “XXX” (where XXX is the 3 digit decimal

display code as mentioned on the sticker in the set). Make sure to key in all

three digits, also the leading zero’s. If the above action is successful,

the front LED will go out (Standby) as an indication that the RC sequence was

correct. After the display option is changed in the NVM, the TV will go to the

Standby mode. If the NVM was corrupted or empty before this action, it will be

initialized first (loaded with default values). This initializing can take up

to 20 seconds.

To

Navigate In SAM, the menu items can be selected with the “CURSOR UP/DOWN” key

on the RC-transmitter. The selected item will be highlighted. When not all menu

items fit on the screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

With

the “CURSOR LEFT/RIGHT” keys, it is possible to: (De) activate the selected menu item. – (De) activate the

selected sub menu. With

the “OK” key, it is possible to activate the selected action.

To

Exit SAM

Use

one of the following methods:

Switch

the TV set to STAND-BY via the RC-transmitter.

Via

a standard RC-transmitter, key in “00” sequence, or select the “BACK” key.

How

to Read the Error Buffer

Use

one of the following methods:

On

screen via the SAM (only when a picture is visible).

Eg:

00

00 00 00 00: No errors detected

23

00 00 00 00: Error code 23 is the last and only detected error.

37

23 00 00 00: Error code 23 was first detected and error code 37 is the last

detected error. Note that no protection

errors can be logged in the error buffer.

How

to Clear the Error Buffer

Use

one of the following methods:

By

activation of the “RESET ERROR BUFFER” command in the SAM menu.

If

the content of the error buffer has not changed for 50+ hours, it resets

automatically.

[Take

notice that some errors need several minutes before they start blinking or

before they will be logged. So in case of problems wait 2 minutes from start-up

onwards, and then check if the front LED is blinking or if an error is logged.]

The

Blinking LED Procedure.

The

blinking LED procedure can be split up into two situations:

Blinking LED procedure LAYER 1 error. In this case

the error is automatically blinked when the TV is put in CSM. This will be only

one digit error, namely the one that is referring to the defective board, which

causes the failure of the TV.

Blinking

LED procedure LAYER 2 error.

Via this procedure, the contents of the error

buffer can be made visible via the front LED. In this case the error contains 2

digits and will be displayed when SDM (hardware pins) is activated. This is

especially useful for fault finding and gives more details regarding the root

cause of the defective board.

When

one of the blinking LED procedures is activated, the front LED will show

(blink) the contents of the error buffer. Error codes greater then 10 are shown

as follows:

1.

“n” long blinks (where “n” = 1 to9) indicating decimal digit

2. A

pause of 1.5 s

3.

“n” short blinks (where “n”= 1 to 9)

4. A

pause of approximately 3 s,

5.

When all the error codes are displayed, the sequence finishes with a LED blink

of 3 s (spacer).

6.

The sequence starts again.

Example:Error

12 8 6 0 0.

After

activation of the SDM, the front LED will show:

1.

One long blink of 750 ms (which is an indication of the decimal digit) followed

by a pause of 1.5 s

2.

Two short blinks of 250 ms followed by a pause of 3 s

3.

Eight short blinks followed by a pause of 3 s

4.

Six short blinks followed by a pause of 3 s

5.

One long blink of 3 s to finish the sequence (spacer).

6.

The sequence starts again.

How

to Activate

Use

one of the following methods:

Activate

the CSM. The blinking front LED will show the layer 1 error(s), this works in

“normal operation” mode or automatically when the error/protection is monitored

by the Standby processor. In case no

picture is shown and there is no LED blinking, read the logging to detect

whether “error devices” are mentioned.

Activate

the SDM. The blinking front LED will show the entire content of the LAYER 2

error buffer, this works in “normal operation” mode or when SDM (via hardware

pins) is activated when the TV set is in protection.

To Activate SDM

Analogue SDM: use the RC-transmitter and key in the code

“062596”, directly followed by the “MENU” (or “HOME”) button. It is possible that, together with the SDM,

the main menu will appear. To switch it “off”, push the “MENU” (or

"HOME") button again.

Digital SDM: use the RC-transmitter and key in the code

“062593”, directly followed by the “MENU” (or "HOME") button. Note: It is possible that, together with the

SDM, the main menu will appear. To switch it “off”, push the “MENU” (or

"HOME") button again.

HOW TO REMOVE REAR COVER - PHILIPS - 42PFL6007K - LCD TV

42 / 47" SETS

- Pulling bottom of back cover upwards.

- Releasing side catch –1

Releasing side catch 2 & 3.

Pulling bottom edge upwards.

Releasing top catch right.

Releasing top catch middle & left.

Releasing top catch right

Some SSBs have a dedicated LVDS connector, requiring pressing

two catches as indicated in the figure, before removing the LVDS cable.

Upon re-connecting the LVDS cable, ensure the catches are locked

after having inserted the LVDS cable.

HOW TO UPGRADE MONITOR MICORPROCESSOR SOFTWARE - SHARP LCD TV - LC-32D41U - LC-32M41U - LC-40C32U

SOFTWARE VERSION UPGRADE

If

“Monitor version” in the process menu is “2.00M”, the monitor microprocessor

software can not be rewritten (because IC2002 has been replaced

with the mask type).

Create

the SD card for monitor microprocessor software version upgrade in the same

manner as explained in the “Main software version upgrade”.

Copy

the binary image file M150Mxxx.SDC (named temporarily) for monitor

microprocessor software version upgrade to the SD card drive.

- Shut off the AC power to the unit (i.e. unplug the AC cord).

- Insert the SD card for version upgrade (prepared as above) into the service socket located lower side from center at terminals, above S-VIDEO terminal in the rear of the unit, in a way that the cut corner of the SD card comes at the upper side.

NOTE:

If the SD card is inserted in a wrong way, the card will go deep inside the

unit beyond retrieval. Take due care to insert the SD card correctly.

- Turn on the AC power (i.e. plug in the AC cord).

- After the unit startup, the system upgrade screen as shown below appears within 10-30 seconds.

CAUTION:

The moment this operation is done, the upgrading of the monitor microprocessor

software starts. While the upgrade is ongoing, never

power off the unit. Otherwise the upgrade will fail and the system may have a

serious damage beyond recovery (inability to start).

A

failure in the process will trigger the upgrade failure screen. The word “NG”

changes to red for the item failed.

NOTE:

In the event of a failure, repeat the upgrading process. If the process

repeatedly fails, it is likely that the hardware is troubled.

- Upon completion of the whole process, the upgrade success screen as shown below appears. You can check the new software version on this screen. The version information appears after the upgrade is complete.

- Shut off the AC power to the unit (unplug the AC cord), and remove the SD card for version upgrade. Now the software version upgrade is complete.

NOTE:

When you are done with the software version upgrade, start the set, go to the

top page of the adjustment process screen and check the monitor microprocessor

software version information.

Video signal

adjustment.

CLICK ON THE PICTURE TO ZOOM IN

Wednesday, October 30, 2013

SHARP LC-32D41U - LC-32M41U - LC-40C32U - SOFTWARE UPGRADE PROCEDURE

SOFTWARE UPGRADE

After replacement of any PWB unit and/or IC for repair,

please note the following.

When replacing the following units, make sure to prepare the

new units loaded with updated software.

MAIN Unit: DUNTKD640FM22 (LC-32D41U)

MAIN Unit: DUNTKD640FM23 (LC-32M41U)

MAIN Unit: DUNTKD640FM21 (LC-40C32U)

IF Unit: DUNTKD643FM22 (LC-32D41U)

IF Unit: DUNTKD643FM23 (LC-32M41U)

IF Unit: DUNTKD643FM18 (LC-40C32U)

Upgrading of each microprocessor software.

Caution: Never “POWER OFF” the unit when software upgrade is

ongoing. Otherwise the system may be

damaged beyond recovery.

Software version upgrade. [The model employs the following

software.]

Main software

Monitor microprocessor software

The main software and the monitor microprocessor software

can be upgraded by using a general-purpose SD memory card.

The followings are the

procedures for upgrading, explained separately for each of the main software,

the monitor microprocessor software.

Main software version upgrade.

- SD memory card of 32MB or higher capacity

- PC running on Windows 98/98SE/ME/2000/XP operating system

- SD memory card reader/writer with USB connectivity.

- SD memory card formatting software. [ Can be downloaded by Panasonic website] Not by Sharp Website.

To upgrade the main software, it is necessary to get ready

the SD card for version upgrade before you start. Follow the steps below and create the SD card for version

upgrade.

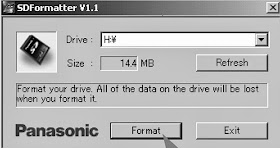

Insert the SD card into the SD card reader/writer.Start the

SD card formatting software. Click [Format]. (When you have the drive options,

select the drive where the SD card is inserted before you proceed.)

When the formatting is over, the following window

appears. Click [OK].

Click [Exit] to finish the formatting.

NOTE: When you are done, take out the SD card once to make sure it is finished, and then insert it again.

Copy the binary image file D41(D41U, M41U, 40C32)UAxxx.SDC

(named temporarily) for version upgrade to the root directory (folder) of the

SD card drive.

NOTE: In the SD card drive, do not store other folders or

unrelated files, or more than one binary image files for version upgrade. Now the SD card for version upgrade is

ready.

TO UPGRADE

- Shut off the AC power (i.e. unplug the AC cord).

- Insert the SD card for version upgrade (prepared as above) into the service socket located lower side from center at terminals, above S-VIDEO terminal in the rear of the unit, in a way that the cut corner of the SD card comes at the upper side. NOTE: If the SD card is inserted in a wrong way, the card will go deep inside the unit beyond retrieval. Take due care to insert the SD card correctly.

- Turn on the AC power (i.e. plug in the AC cord).

- After the unit start-up, the system upgrade screen as shown below appears within 20-40 seconds.

NOTE: In the event of a failure, repeat the upgrading

process. If the process repeatedly fails, it is likely that the hardware is

troubled.

- Upon completion of the whole process, the upgrade success screen as shown below appears. You can check the new software version on this screen. The version information appears after the upgrade is complete.

- Shut off the AC power to the unit (unplug the AC cord), and remove the SD card for version upgrade.

- Now the software version upgrade is complete.

Tuesday, October 29, 2013

JBL ARC SUB _ TEST PROCEDURE _ SCHEMATIC DIAGRAM (Circuit Diagram) _ Discrete Output, High Current 8" Powered Subwoofer

EXPLODED VIEW

CLICK ON THE PICTURES TO ZOOM IN

PRE-AMP SCHEMATICPRE-AMP PWB

POWER AMP SCHEMATIC

POWER AMP PWB

TEST PROCEDURE

General Function

UUT = Unit Under Test

- Connect both right and left line level inputs (RCA) to signal generator and UUT. Use Y-cable if necessary from mono source. VOLUME control should be full counterclockwise.

- Turn on generator, adjust to50mV, 50 Hz.

- Plug in UUT; red LED should be ON. Turn VOLUME control full clockwise.

- LED should turn Green; immediate bass response should be heard and felt from port tube opening.

- Turn off generator, turn VOLUME control fully counterclockwise, disconnect RCA cables.

- Connect one pair of speaker cables to either high level input terminal on UUT. Cables should be connected to an integrated amplifier fed by the signal generator.

- Turn on generator and adjust so that speaker level output is 2.0V, 50 Hz. Turn VOLUME control full clockwise.

- Green LED should light, immediate bass response should be heard and felt from the port tube opening.

- Follow steps 1-4 above, using a sweep generator as a signal source.

- Sweep generator from 20Hz to 300Hz. Listen to the cabinet and drivers for any rattles, clicks, buzzes or any other noises. If any unusual noises are heard, remove driver and test.

- Remove driver from cabinet; detach + and - wire clips.

- Check DC resistance of driver; it should be [3.0] ohms.

- Connect a pair of speaker cables to driver terminals. Cables should be connected to an integrated amplifier fed by a signal generator and adjust so that speaker level output is [5.0V].

- Sweep generator from 20Hz to 1kHz. Listen to driver for any rubbing, buzzing, or other unusual noises.

JBL LS 120 P (230V) Powered sub-woofer _ SCHEMATIC DIAGRAM [Circuit Diagram]

EXPLODED VIEW

CLICK ON THE PICTURES TO MAGNIFY

SMPSSPECIFICATIONS

Frequency Response 25Hz – 150Hz

Amplifier RMS Power

400 Watts

Amplifier Peak Dynamic Power: 700 Watts

Crossover Frequency 50Hz – 150Hz; 24dB/octave, continuously

adjustable

Driver 300mm (12") PolyPlas

Dimensions (H x W x D) 487mm x 375mm x 425mm (enclosed only)

(19-3/16" x 14-3/4" x 16-3/4")

Dimensions (H x W x D) 500mm x 375mm x 438mm (with feet,

controls, grille, etc.) (19-11/16" x 14-3/4" x 17-1/4")

Weight 25.8kg (57 lb.