Monday, February 29, 2016

Philips 42PFL3041, CCE LK420 – SMPS and Main digital board SCHEMATIC

Professional technician for all kind of electronic equipment. Doing since 1974.

Philips 21.5 inch and Philips 23 inch TV Monitors – 221TE4LB – 231TE4LB SMPS - Audio amp board schematics

SMPS, Audio amp and headphone, Panel failure symptoms

Philips LCD TV Monitor SMPS 7154313P03000003S SCHEMATIC

Philips

LCD TV Monitor SMPS 715G3973P01W22003M

SCHEMATIC

Audio amp and headphone

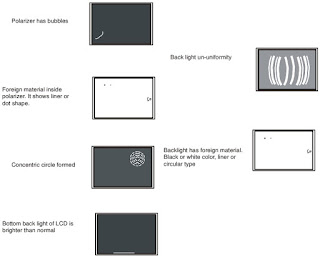

Panel failure symptoms

Failure Mode of Panel

It is not necessary to repair circuit board. Simply follow the mechanical instruction on this manual to eliminate failure by replace LCD panel.

Click on the pictures to magnify

Professional technician for all kind of electronic equipment. Doing since 1974.

Fostex MR16HD – Fostex MR16HD-CD – How to enter service mode – checks – Error Codes - SMPS circuit diagram

Fostex MR16HD – Digital Multi-Tracker – Service Mode – SMPS schematic – Service mode checks - Error Codes

ERROR CODEs

FILE ERR: 08 => The MBR (Master Boot Record) region, BPB (Boot Parameter Block) region or the cluster chain might be in a bad condition. => Back up data in the internal HD to PC and format it.

FILE ERR: 02 - FILE ERR: 11 => The file format is illegal. => Check if the ADL / WAV files included in the target file are in good condition from PC side.

FILE ERR: 0D => No access authorization to the file or folder.

FILE ERR: 1C => No disk remaining capacity

SMPS circuit diagram and PWB

Entering Service Menu> Connect the AC cable and power on MR16. After the bootup procedure is completed, the display on the right will appear on the MR16 LCD.

> Press the [MENU/ENTER] dial while holding down the [STOP] and [POWER] keys. If you do so, "Service Mode" is displayed on the MR16 LCD.

CAUTION: If the [POWER] key is held down for more than three seconds, MR16 turns off. Please be careful to expedite the above manipulation 2).

> Rotate the [MENU/ENTER] dial and select “Service Mode”. Then, press the [MENU/ENTER] dial. You can see that the following service menus will appear on the MR16 LCD.

> Select one of the service menus you would like to execute and press the [MENU/ENTER] dial.

Version

In the “Version” service menu, the current MR16 software version as well as the corresponding software programming date can be checked.

In the “Version” service menu, the current MR16 software version as well as the corresponding software programming date can be checked.

After selecting the “Version” menu, press

the [MENU/ENTER] dial to check the current software version and the programming

date.

By

pressing the STOP key, MR16 returns to the service menu select condition.

The

“Version Up” service menu allows you to update the MR16 software by placing the

software update file in the root directory tree of the MR16 3.5” internal hard

disk.

Advanced Format

MR16 checks the remaining capacity / partition information written on the internal HD in the bootup process after powering on. In case this information does not match the current HD condition, the “Advanced Format” service menu can be used. For example, even if no song has been created (recorded) but the remaining capacity indicates only 10MB, execute the “Advanced Format” menu.

Remember that executing the “Advanced Format” deletes all the songs recorded on the internal HD.

Upon completion of “Advanced Format”, the message “Boot Sector Clear” appears on the LCD

[In case MR16 is not booted up correctly and displays an alert message such as “Please Wait!” permanently, power if off once. Then, while holding down the [STOP] key, power on MR16. This mode allows to boot up without loading any recorded songs. Next, execute the “Advanced Format” menu.]

CD-RW

Disk Erase

Executing the “Disk Erase” service menu erases all existing song data on the CD-RW disk put into the MR16HD/CD internal CD-R/RW drive.

1) Rotate the [MENU/ENTER] dial and select “CD-RW”. Then, press the [MENU/ENTER] dial.

Executing the “Disk Erase” service menu erases all existing song data on the CD-RW disk put into the MR16HD/CD internal CD-R/RW drive.

1) Rotate the [MENU/ENTER] dial and select “CD-RW”. Then, press the [MENU/ENTER] dial.

2)

Rotate the [MENU/ENTER] dial and select “Disk Erase”. Then, press the

[MENU/ENTER] dial.

3)

To go on, press the [MENU/ENTER] dial while holding down the [REC] key.

4)

The CD-RW disk erasing procedures begin. “Erasing...” will appear. It will take

about one minute to complete the procedures.

5)

Upon completion, “Completed!” will appear on the LCD.

Display

Test

This menu checks if the EFFECT SEND / PAN / REVERB/DELAY pots & faders / self-illuminating tact switches are working properly.

1) After selecting the “Display Test” menu, press the [MENU/ENTER] dial

This menu checks if the EFFECT SEND / PAN / REVERB/DELAY pots & faders / self-illuminating tact switches are working properly.

1) After selecting the “Display Test” menu, press the [MENU/ENTER] dial

2)

Press the [MENU/ENTER] dial again. If you do so, the display on the right will

appear on the MR16 LCD. Each value the

EFFECT SEND / PAN / TO STEREO BUSS LEVEL / REVERB/DELAY pots & faders

position. Rotate the EFFECT SEND / PAN pots and move the faders to check if the

value changes from "0" to "F" in hexadecimal depending on

the pots / fades position as follow.

EFFECT

SEND Pots 1 ~ 8: 0 (CCW) ~ F (CW)

PAN pots 1 ~ 8: 0 (CCW) ~ F (CW)

TO STEREO BUSS LEVEL pot: 0 (CCW) ~ F (CW)

REVERB/DELAY pot: 0 (CCW) ~ F (CW)

Channel faders (1 ~ 8, 9/10, 11/12, 13/14, 15/16): 0 (down) ~ F (up)

Master fader: 0 (down) ~ F (up)

PAN pots 1 ~ 8: 0 (CCW) ~ F (CW)

TO STEREO BUSS LEVEL pot: 0 (CCW) ~ F (CW)

REVERB/DELAY pot: 0 (CCW) ~ F (CW)

Channel faders (1 ~ 8, 9/10, 11/12, 13/14, 15/16): 0 (down) ~ F (up)

Master fader: 0 (down) ~ F (up)

3)

After checking, press the [MENU/ENTER] dial to proceed the next Display Test.

The next test is to check if the self-illuminating tact switches are lit in

red.

Check if the self-illuminating tact switches are properly lit in red.

Check if the self-illuminating tact switches are properly lit in red.

4)

After checking, press the [MENU/ENTER] dial to proceed the next Display Test.

The next test is to check if the self-illuminating tact switches are lit in

green.

Check if the self-illuminating tact switches are properly lit in green.

Check if the self-illuminating tact switches are properly lit in green.

5)

After checking, press the [MENU/ENTER] dial to proceed the next Display Test.

The next test is to check if the self-illuminating tact switches are lit in

umber.

Check if the self-illuminating tact switches are properly lit in orange.

Check if the self-illuminating tact switches are properly lit in orange.

6)

After checking, press the [MENU/ENTER] dial to proceed the next Display Test.

The next test is to check if the tact switches on the MR16 top panel except the

POWER SW is in good contact. If the tact switch is pressed, the corresponding

asterisk mark on the MR16 LCD will go out. If not, the tact switch might be

worn out and be replaced.

After all the tact switches are confirmed to be in good contact, the display on the right will appear on the MR16 LCD.

After all the tact switches are confirmed to be in good contact, the display on the right will appear on the MR16 LCD.

Bus

Check

This menu checks if various bus signals connected to the CPU are correctly working or not.

1) After selecting the “Bus Check” menu, connect the foot SW to the foot SW jack and the USB cable between the USB and USB HOST ports.

2) Press the [MENU/ENTER] dial to initiate the Bus Check mode.

This menu checks if various bus signals connected to the CPU are correctly working or not.

1) After selecting the “Bus Check” menu, connect the foot SW to the foot SW jack and the USB cable between the USB and USB HOST ports.

2) Press the [MENU/ENTER] dial to initiate the Bus Check mode.

AUDIO BUS

The AUDIO BUS setting is fixed at “THRU” in this menu. In the “THRU” setting, the A/D and D/A converters are internally connected. Also the CHAN A/C and B/D PAN setting are set to left and right respectively. Thus, the signals fed to CHAN A and C are summed and output from the STEREO OUT L and the signal fed to CHAN B and D are summed and output from the STEREO OUT R.

This mode is convenient when checking the input circuit.

The AUDIO BUS setting is fixed at “THRU” in this menu. In the “THRU” setting, the A/D and D/A converters are internally connected. Also the CHAN A/C and B/D PAN setting are set to left and right respectively. Thus, the signals fed to CHAN A and C are summed and output from the STEREO OUT L and the signal fed to CHAN B and D are summed and output from the STEREO OUT R.

This mode is convenient when checking the input circuit.

ATA

BUS

The “OK” sign indicates that the ATA bus communication between the internal HD and the CPU is properly made. If the “NG” sign appears, something must be wrong with the ATA bus communication.

The “OK” sign indicates that the ATA bus communication between the internal HD and the CPU is properly made. If the “NG” sign appears, something must be wrong with the ATA bus communication.

INPUT

SEL

The “INPUT SEL” indicates the number corresponding to the INPUT A SELECT switch setting as follow.

GTR CLEAR: 2

GTR DISTORTION: 1

MIC/LINE: 3

FOOT SW

When an unlatched type foot switch is connected and it is pressed, the “ON” indication will appear. If the foot switch is released or is not connected, the “OFF” sign will appear.

The “INPUT SEL” indicates the number corresponding to the INPUT A SELECT switch setting as follow.

GTR CLEAR: 2

GTR DISTORTION: 1

MIC/LINE: 3

FOOT SW

When an unlatched type foot switch is connected and it is pressed, the “ON” indication will appear. If the foot switch is released or is not connected, the “OFF” sign will appear.

USB

BUS

If the “USB BUS” section indicates the “OK” sign 3 ~ 5 seconds after the “WAIT..” sign is displayed, the USB HOST function works properly. If the “NG” sign is displayed, press the [MENU/ENTER] dial and then try to enter the Bus Check mode again by pressing the [MENU/ENTER] dial.

ATAPI BUS

The “OK” sign indicates that the ATAPI bus communication between the CD-R/RW drive and the CPU is properly made. If the “NG” sign appears, something must be wrong with the ATAPI bus communication.

If the “USB BUS” section indicates the “OK” sign 3 ~ 5 seconds after the “WAIT..” sign is displayed, the USB HOST function works properly. If the “NG” sign is displayed, press the [MENU/ENTER] dial and then try to enter the Bus Check mode again by pressing the [MENU/ENTER] dial.

ATAPI BUS

The “OK” sign indicates that the ATAPI bus communication between the CD-R/RW drive and the CPU is properly made. If the “NG” sign appears, something must be wrong with the ATAPI bus communication.

Professional technician for all kind of electronic equipment. Doing since 1974.

Blaupunkt Auto-Radio – Exploded view – Circuit Diagram – Audi Chorus – Audi Concert

Used ICs: ST6280 – LM258D – TDA1575T – TDA1597T – SDA4331 – TL0721DR – TDA1078A – RC4558 – HA12194 – HA12199 – MC68HC05C8 – MC68HC05B32 – MC74HC132M1R – LM258D – MC33079D – MC14551BC – TDA7342 – TDA1592

Audi Chorus - 7 646 243 380

Audi Chorus A8 - 7 647 243 380

Audi Concert - 7 646 248 380

Audi Concert A8 - 7 647 248 380

Audi Concert Navi - 7 647 249 380

Audi Chorus

This car radio can be operated with 2 passive front loudspeakers and of choice with 2 active rear loudspeakers. The switching-over takes place by means of the diagnosis bus.Ex-factory condition: Default values (via diagnosis bus)

Fader active

Rear loudspeakers connectable

Audi Concert

This car radio can be operated with 2 passive and 2 active loudspeakers or as a Bose sound system. In addition the unit can be switched to the US mode. The switching-over takes place by means of the diagnosis bus.

Ex-factory condition: Default values (via diagnosis bus)

Standard loudspeakers

Europe mode.

Exploded views

Connector pin assignment

Circuit Diagram (Schematic)

Main board

HF Module

Keyboard

Click on the schematics to zoom in

Professional technician for all kind of electronic equipment. Doing since 1974.

Sunday, February 28, 2016

Yamaha YST SW320 – Subwoofer - Circuit diagram - adjustments

Amplifier

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250W/5

Frequency Response . . . . . . . 20 Hz to 160 Hz (-24 dB/oct.)

Power Supply

U, C models . . . . . . . . . . . . . . . . . . . . . . . . . AC120V, 60 Hz

A model . . . . . . . . . . . . . . . . . . . . . . . . . . . . AC240V, 50 Hz

B, G models . . . . . . . . . . . . . . . . . . . . . . . . . AC230V, 50 Hz

R, T models . . . . . . . . . . . . AC110/120/220/240V, 50/60 Hz

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60W

Dimensions (W x H x D) - 340 x 432 x 370 mm (13-3/8"

x 17" x 14-9/16")

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 kg (37 lbs. 7

oz)

Disassembly

Removal

of Front Panel Ass'y

Remove 4 screws (1) and then remove the Front Panel Ass'y in Fig. 1.

Use an Allen wrench (3mm) to unscrew the Front Panel Ass'y

Remove 4 screws (1) and then remove the Front Panel Ass'y in Fig. 1.

Use an Allen wrench (3mm) to unscrew the Front Panel Ass'y

Remove

8 screws (2) and then remove the Base Ass'y in Fig. 2.

Remove 4 screws (3) and then remove the Loud Speaker in Fig. 2.

Remove 4 screws (3) and then remove the Loud Speaker in Fig. 2.

Remove

12 screws (4) in Fig. 3.

Arrow marks (<=) are printed to identify the screws to be removed.

Arrow marks (<=) are printed to identify the screws to be removed.

When

assembling the Rear Panel, check to ensure that the gasket is not damaged so as

to prevent air leakage from occurring.

Installation

of emblem

1. Put the emblem into the cabinet at the specified position.

2. Place a piece of cloth/wood on top of the emblem.

3. Using a mallet, hammer the emblem in place through the cloth/wood.

Use special care not to cause damage to the emblem or cabinet while hammering the emblem.

1. Put the emblem into the cabinet at the specified position.

2. Place a piece of cloth/wood on top of the emblem.

3. Using a mallet, hammer the emblem in place through the cloth/wood.

Use special care not to cause damage to the emblem or cabinet while hammering the emblem.

Installation

of power switch

Rapid cures bond (such as 5 minute epoxy) is required to fix the power switch.

Apply rapid cures bond (such as 5 minute epoxy) to the power switch (the area which contacts the rear panel), insert it in the rear panel and make sure it is fixed.

(Inserting the power switch in the rear panel only would not be sufficient for its secure installation.)

Rapid cures bond (such as 5 minute epoxy) is required to fix the power switch.

Apply rapid cures bond (such as 5 minute epoxy) to the power switch (the area which contacts the rear panel), insert it in the rear panel and make sure it is fixed.

(Inserting the power switch in the rear panel only would not be sufficient for its secure installation.)

Circuit diagram

PWB - Foil side

For the power amplifier which has been repaired, it is absolutely necessary to confirm that a correct waveform is obtained at points indicated by A and B in the schematic diagram according to the following procedure.

Idling Adjustment

To

stabilize operation of the amplifier, turn ON the power with no input signal

and wait for 1 or 2 minutes in non loaded condition before the adjustment. Adjust VR1 so that the voltage between

terminals TP11 and TP12 is DC 50mV to 250mV.

Professional technician for all kind of electronic equipment. Doing since 1974.

LG47LS5700-UA 3D LCD TV - How to upgrade the firmware – EDID data download – LAN-Port setting – Audio Amplifier Circuit Diagram

LG47LS5700-UA

- LG47LS579C-UA - LG47LS5700 - LG47LS579C - LG

32”, 42”, 47”, 55”, 65” 3DLCD TV with

LA22E chassis

North/Latin

America Europe/Africa

Asia/Oceania

MAC

Address, ESN Key and Widevine Key download

1.Play

file: keydownload.exe

Communication

Port connection

1) Key Write: Com 1,2,3,4 and 115200 (Baud rate)

2) Barcode: Com 1,2,3,4 and 9600 (Baud rate)

1) Key Write: Com 1,2,3,4 and 115200 (Baud rate)

2) Barcode: Com 1,2,3,4 and 9600 (Baud rate)

Download

process

1) Select the download items.

2) Mode check: Online Only

3) Check the test process

> US, Canada models: DETECT > MAC_WRITE > WIDEVINE_WRITE

> Korea, Mexico models: DETECT > MAC_WRITE > WIDEVINE_WRITE

4) Play : START

5) Check of result: Ready, Test, OK or NG.

1) Select the download items.

2) Mode check: Online Only

3) Check the test process

> US, Canada models: DETECT > MAC_WRITE > WIDEVINE_WRITE

> Korea, Mexico models: DETECT > MAC_WRITE > WIDEVINE_WRITE

4) Play : START

5) Check of result: Ready, Test, OK or NG.

Communication Port connection

1) Connect: PCBA Jig > RS-232C Port == PC > RS-232C Port

Download

1) US, Canada, Mexico models (11Y LCD TV + MAC + Widevine + ESN Key)

2)

Korea and Philippine models (11Y LCD TV + MAC + Widevine Only)

Inspection

> In INSTART menu, check these keys.

LAN PORT INSPECTION (PING TEST)

Equipment setting

1) Play the LAN Port Test PROGRAM.

2) Input IP set up for an inspection to Test Program.

IP Number : 12.12.2.2.

Connect:

SET > LAN PORT == PC > LAN PORT

LAN

PORT inspection (PING TEST)

1) Play the LAN Port Test Program.

2) Connect each other LAN Port Jack.

3) Play Test (F9) button and confirm OK Message.

4) Remove LAN CABLE

1) Play the LAN Port Test Program.

2) Connect each other LAN Port Jack.

3) Play Test (F9) button and confirm OK Message.

4) Remove LAN CABLE

EDID

Download

Since

EDID data is embedded, EDID download JIG, HDMI cable and D-sub cable are not

needed.

Adjust by using remote controller.

Adjust by using remote controller.

Download

method

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) If Download is successful, OK is display, but If Download is failure, NG is displayed.

(5) If Download is failure, Re-try downloads.

Caution: When EDID Download, must remove RGB/HDMI Cable.

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) If Download is successful, OK is display, but If Download is failure, NG is displayed.

(5) If Download is failure, Re-try downloads.

Caution: When EDID Download, must remove RGB/HDMI Cable.

EDID DATA

Audio amplifier schematic

Click on the pictures to magnify

Professional technician for all kind of electronic equipment. Doing since 1974.

LG RAD226B - RAS376BF - Mini Hi-Fi System – Troubleshooting

NO

SOUND

There is no sound output in the TUNER FUNCTION.

There is no sound output in the TUNER FUNCTION.

check

and replace IC401, TU100 on MAIN board.

1) Check if TUNER_LR is entered from Pin1,3 of TU100 to IC401(Pin23, 24).

=> If no signals, Check +3.3 V for Tuner power.

=> Check if the Tuner control signals (CLK, DAT, CE, RST, SLT) are entered from IC102 to TU100.

If it doesn’t work, replace TUNER with a new one.

2) Check if DAC_BCK, DAC_LRCK, & DAC_MCLK are entered from IC501 to IC202.

3) Check if ADC_DATA is entered from IC401 to IC801.

=> If no signal, check +5 V & +3.3 V(ADC) for IC401. If is NG, replace it a new one.

4) Check the following I2S audio signal flow from IC801 to IC602. (Refer to Item 5-1.)

=> If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay.

=> If AMP is damaged, replace it with a new one.

=> Check if the Tuner control signals (CLK, DAT, CE, RST, SLT) are entered from IC102 to TU100.

If it doesn’t work, replace TUNER with a new one.

2) Check if DAC_BCK, DAC_LRCK, & DAC_MCLK are entered from IC501 to IC202.

3) Check if ADC_DATA is entered from IC401 to IC801.

=> If no signal, check +5 V & +3.3 V(ADC) for IC401. If is NG, replace it a new one.

4) Check the following I2S audio signal flow from IC801 to IC602. (Refer to Item 5-1.)

=> If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay.

=> If AMP is damaged, replace it with a new one.

There is no sound output in the AUX FUNCTION

Check and replace I1) Check AUX_L/R signals to IC401 (Pin7, 8).

2) Check if DAC_BCK, DAC_LRCK, & DAC_MCLK are entered from IC801 to IC401.

3) Check if ADC_DATA is entered from IC401 to IC801.

=> If no signal, check +5 V & +3.3 V(ADC) for IC401. If is NG, replace it a new one.

4) Check the following I2S signal flow from IC801 to IC602. (Refer to Item 5-1.)

=> If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay.

=> If AMP is damaged, replace it with a new one.C401 on MAIN board.

There is no sound output in the USB FUNCTION

Check and replace IC801 on MAIN board & IC505 on USB board.

1.Check +5VU to USB board.

=> If the USB LED are turned on, the voltage is okay, if so not, check +5.6 V to pin4 of CN501.

2) Check USB D± from MAIN board to USB board.

a. Check USB_DN/DP signals to IC801(pin116, 117).

b. Check USB± signals from IC504 to CN501 (pin2, 3).

=> If there is any trouble, check the power for each IC. The power is normal but , if the signal waveform to the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block”.

There is no sound output by DIGITAL AUDIO AMP DAMAGE [BY DIGITAL AUDIO AMP DAMAGE (IN ALL FUNCTIONS)]

Check and replace IC700, IC701(Only RAT376) on MAIN board.

1.Check FL±, FR± & SW± signals from IC602 to IC700 & 701 each input function.

=> If no signal, check if I2S audio signals are entered to IC602.

Refer to “I2S audio signal interface” on Item 5-1.

2) Check PVDD.

=> If PVDD is abnormal, check the SMPS.

3) Check +12 V for driving the gate of AMP IC.

a. All the powers are normal, but if +12 V is low, there is possible for AMP IC to be damaged.

b. Remove L711, L712, L713 and L714 one by one.

When removed a inductance, if +12 V is recovered, AMP IC connected to it was damaged.

c. Replace AMP IC with a new one.

4) Check the impedance between IC700/IC701_OUT-A/OUT-B & GND.

a. If the impedance is 0 Ω, AMP IC must be damaged.

b. After removing the heat sink, replace it with a new one.

There

is no sound output in the CD FUNCTION

Check

and replace IC602, IC801 on MAIN board.

1)

Check CD_BCK, CD_LRCK, & CD_DATA signals from IC302 to IC801.

=> If no signal, check if the RF & servo signals from MD is entered to IC302.

Refer to the “No operation of MD” guide on Item 4.

2) Check the following I2S signal flow. < I2S audio signal Interface >

- DAC_BCK: IC801_Pin87 --> IC602_Pin4

- DAC_LRCK : IC801_Pin88 --> IC602_Pin5 (44.1 kHz)

- DAC_DATA : IC801_Pin83 --> IC602_Pin6,9

- DAC_MCLK : IC801_Pin86 --> IC401_Pin44

=> If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block”

=> If no signal, check if the RF & servo signals from MD is entered to IC302.

Refer to the “No operation of MD” guide on Item 4.

2) Check the following I2S signal flow. < I2S audio signal Interface >

- DAC_BCK: IC801_Pin87 --> IC602_Pin4

- DAC_LRCK : IC801_Pin88 --> IC602_Pin5 (44.1 kHz)

- DAC_DATA : IC801_Pin83 --> IC602_Pin6,9

- DAC_MCLK : IC801_Pin86 --> IC401_Pin44

=> If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block”

When

no sound output in the CD function, you cannot listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for

checking the LASER FOCUSING ACTUATOR.

Check

and replace IC301, IC302 on MAIN board.

The

focusing actuator makes the laser beam keep a regular interval with the surface

of a CD disc.

1) Check the FOD signal from Pin13 of IC302.

> If no signal, check 3.3 V(RF) and X301.

2) Check F- & F+ from IC301 to CN301 for driving the focusing actuator.

> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN301 and MD.

4) Check the MD.

> If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

1) Check the FOD signal from Pin13 of IC302.

> If no signal, check 3.3 V(RF) and X301.

2) Check F- & F+ from IC301 to CN301 for driving the focusing actuator.

> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN301 and MD.

4) Check the MD.

> If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

When

no sound output in the CD function, you can not listen to music reading data

from a CD disc if the pickup module in MD doesn’t work. This step is for

checking the LASER TRACKING ACTUATOR.

Check

and replace IC301, IC302 on MAIN board.

The

tracking actuator makes the laser beam be positioned in the center of a track

on CD disc.

1) Check the TRD signal from Pin14 of IC302.

=> If no signal, check 3.3 V(RF) and X301.

2) Check TR- & TR+ from IC301 to CN301 for driving the tracking actuator.

=> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN301 and MD.

4) Check the MD.

=> If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Check the function after changing another MD.

1) Check the TRD signal from Pin14 of IC302.

=> If no signal, check 3.3 V(RF) and X301.

2) Check TR- & TR+ from IC301 to CN301 for driving the tracking actuator.

=> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN301 and MD.

4) Check the MD.

=> If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Check the function after changing another MD.

When no sound output in the CD function, you cannot listen to music reading data from a CD disc if the servo motors in MD don’t work. This step is for checking the TRAY OPEN / CLOSE MOTOR among them.

Check and replace IC301, IC302 on MAIN board.

1) Check MOT_OPEN & MOT_CLOSE signals from Pin104, 105 of IC801 to IC301.

=> If no signal, check +1.8 V & + 5 V to IC301.

2) Check LOAD± from IC301 to CN303 for driving the tray open / close motor. It is about 3.85 Vp-p.

=> If no signal, check +5 V to IC301. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN303 and MD.

4) Check the MD.

=> If the tray motor is sort-circuit or has any trouble, it can not open or close the tray.

Check the function after changing another MD.

When no sound output in the CD function, you cannot listen to music reading data from a CD disc if the servo motors in MD don’t work. This step is for checking the SLED MOTOR among them.

Check and replace IC301, IC302 on MAIN board.

1) Check the SLDO signal from Pin15 of IC302.

=> If no signal, check 3.3 V(RF) and X301.

2) Check the SLED+ & SLED- from IC301 to CN303 for driving SPINDLE motor. It is about 2.9 Vp-p.

=> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN303 and MD.

4) Check the MD.

=> If the sled motor is sort-circuit or has any trouble, it can not move the pickup module.

Check the function after changing another MD.

When

no sound output in the CD function, you cannot listen to music reading data

from a CD disc if the servo motors in MD don’t work. This step is for checking

the SPINDLE MOTOR among them

Check

and replace IC301, IC302 on MAIN board.

1)

Check the SPDO signal from pin16 of IC302.

=> If no signal, check 3.3 V(RF) and X301.

2) Check the SPIN- & SPIN+ from IC301 to CN303 for driving SPINDLE motor. It is about 3.6 Vp-p.

=> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN303 and MD.

4) Check the MD.

=> If the spindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Check the function after changing another MD.

=> If no signal, check 3.3 V(RF) and X301.

2) Check the SPIN- & SPIN+ from IC301 to CN303 for driving SPINDLE motor. It is about 3.6 Vp-p.

=> If no signal, check +1.8 V and +5 V for IC301.

3) Check if the FFC cable is solidly connected between CN303 and MD.

4) Check the MD.

=> If the spindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Check the function after changing another MD.

VFD IS NOT DISPLAYED WHEN POWER ON THE SET. When power on the set, any icons or characters on VFD are not displayed.

Check and replace DIG502 on FRONT board.

1.Check if VKK, FL+ and FL- are output from SMPS to VFD via the MAIN board.

2) Check if IC102 outputs VFD_D0, VFD_CLK and VFD_STB to the FRONT board.

3) Check the GR signal(pulse signal) of IC501 on the FRONT board.

Check the SG signal(pulse signal) of IC501 on the FRONT board.

=> If the GR and SG signal isn’t output, replace IC501 with a new one.

=> If the GR and SG signal is output, replace DIG502 with a new one.

NO

BOOTING WHEN POWER ON THE SET

The set doesn’t work when press the power button on the front board or the remote control.

The set doesn’t work when press the power button on the front board or the remote control.

FLASH

MEMORY - check and replace IC101 on MAIN board.

1.Check

3.7 V to CN304 and CN105 in standby mode.

=> If there is no 3.7 V, check the SMPS.

2) Check 5.6 V, 12 V, F+, F- and PVDD when power on the set.

- If the set doesn’t work regardless of what the KEY1 changes high to low while pressing the power button.

X101 and X102 work normally but, if you cannot power on the set, replace IC101 with a new one on the MAIN board.

=> If there is no 3.7 V, check the SMPS.

2) Check 5.6 V, 12 V, F+, F- and PVDD when power on the set.

- If the set doesn’t work regardless of what the KEY1 changes high to low while pressing the power button.

X101 and X102 work normally but, if you cannot power on the set, replace IC101 with a new one on the MAIN board.

Professional technician for all kind of electronic equipment. Doing since 1974.

LG RAD226B - RAS376BF Mini Hi-Fi System – SMPS and Amp -Circuit Diagram - Troubleshooting

AMPLIFIER 110 W + 110 W (4 Ω at 1 kHz, THD 10 %)

SPEAKER

Type 2 Way 2 Speaker

Impedance 4 Ω

Rated Input Power 110 W

Max. Input Power 220 W

SPEAKER

Type 2 Way 2 Speaker

Impedance 4 Ω

Rated Input Power 110 W

Max. Input Power 220 W

SMPS Circuit diagram

SMPS PWB

Micom and AD

Power amplifier

SMPS Troubleshooting

NO

POWER

The unit doesn’t work: no power problem.

The unit doesn’t work: no power problem.

Check

and replace D929 on SMPS board.

1)

Check the Anode-Cathod Voltage of D929 with a digital multi-meter, it is

normally 0.2 ~ 0.3 V.

=> If it doesn’t have any voltage, it’s destroyed. Replace it with a new one.

=> If it doesn’t have any voltage, it’s destroyed. Replace it with a new one.

NO

POWER

Check

and replace F901, BD901, TH901 on SMPS board.

1)

Check if the fuse F901 is open or short-circuit.

2) Check if the bridge diode DB901 is short-circuit by over current with a digital multi meter.

3) Check if the NTC thermistor TH901 is normal or open.

2) Check if the bridge diode DB901 is short-circuit by over current with a digital multi meter.

3) Check if the NTC thermistor TH901 is normal or open.

Professional technician for all kind of electronic equipment. Doing since 1974.

Subscribe to:

Comments (Atom)