When

troubleshooting the set, the defective panel requiring replacement or

additional repair must be located. The Power supplies, Deflection, 1fH inputs,

and Audio outputs are located on the Family board. The 2fH, CRT drive, and

Deflection drive circuits are located on the Trident board.

If the set turns ON without a picture or sound, first check the power supplies

located on the Family board. If the set comes ON, then shuts Off, there may be

a problem with the shutdown circuits which are located on the Family board. If

the picture is missing, but sound and high voltage are present, the problem may

be located on the Trident panel.

TV

Signal Processor

Red,

Green, and Blue from the Trident IC is input on Pins 30, 31, and 32 of 7221, TV

Display Processor. The RGB/YUV matrix changes the signal to a YUV signal before

feeding it to a Color level control circuit. The signal is fed to the RGB

insertion circuits where the OSD is inserted. The signal is then fed to a White

Point and Brightness Control circuit and then to the CRT panel. The White Point

and Output Amplifier have the Drive controls and Cutoff controls. Input from

the ABL line on Pin 43 makes adjustments in the brightness levels to adjust for

changes in beam current. The Cutoff pulses from the CRTs are fed to Pin 44 to

the Cathode Calibration circuit. The Cathode Calibration circuit adjusts the

cutoff levels of the CRT to maintain the correct gray scale tracking.

When the

set is first turned On, a calibration pulse is output on the RGB lines. The

Cathode Calibration circuit monitors this pulse on the Cutoff line to set the

Black level and the maximum drive voltage for the cathode. Once the Calibration

has taken place, the Output Amplifier switches to the RGB drive signal as the

output. Horizontal and Vertical Sync is fed to 7600 on Pins 23 and 24. IC 7600

processes the sync to provide the geometry for the picture. Horizontal drive is

output to the sweep circuit on Pin 8. Vertical drive is output on Pins 1and 2.

East West drive is output on Pin 3. Sandcastle (SCO) is output on Pin 9.

Horizontal Feedback (HFB) from the sweep circuit is fed into the Phase Loop to

phase correct the Horizontal drive. IC 7221 is controlled by the Hercules

Processor on the Family Board via the I2C buss on Pins 10 and 11. Transistors

7226 and 7227 levels shifts the I2C buss level between 5 and 3.3 volts.

Geometry and Drive settings are stored in the Memory IC located on the Family

Board.

Deflection:

Sync

Whatever

signal is applied to the L05 chassis, it will display the picture in a 1080i format.

This means that the Line or Horizontal frequency is always 33.75 kHz. The

Vertical or Frame rate is 60 Hz.

Vertical Sync is output from the Trident IC 7201 on Pin 35. The signal is

buffered by Transistor 7203 before being fed to the TV display processor and TV

Microcontroller. In the same manner Horizontal Sync is output on Pin 34 and is

buffered by Transistor 7204.

Synchronization section circuit

Deflection

Horizontal

drive from 7221 is fed to Transistor 7404 located on the Family board. This

drive circuit has two power sources. During startup, it is powered by the +6

volt supply. Once the High Voltage circuit is running, it is powered by Pin 9

of the IFT. 7404 drives Transformer 5402 which drives the HOT (Horizontal

Output Transistor). The HOT drives the IFT and the Horizontal Deflection Coil.

The IFT is powered by the VBAT (141 volt) supply.

The IFT produces High voltage, Focus voltage and G2 voltage to drive the CRT.

In addition, a 200 volt supply is produced to drive the CRT panel, a +14 and

-14 volt supply for the Vertical output, Filament voltage, +200 volt

VideoSupply, and a +12V_lot supply.

Transistor 7408 monitors the IFT secondary to sense the presence of over

voltage. If the High Voltage goes High, the voltage on Pin 6 of the IFT will go

High. When the voltage on diode 6480 exceeds 15 volts, transistor 7408 will

turn On. If 7408 turns On, it will turn 7407 On causing the x_ray protect line

to go Low. The Processor will then shut the set down. In addition the EW_DRIVE

circuit is monitored. If the EW_DRIVE fails, transistor 7406 will turn On

constantly placing a dc voltage on the source. This will turn 7407 On. IC 7451

is the Vertical Output IC. It is powered by the +14 and -14 volt supply from

the IFT.

The Vertical pulse is rectified by 6458, keeping the V_PROTN line High. If the

vertical output should fail, the V_PROTN line will go Low. The Hercules

processor will then shut the set down.

Line-Frame deflection

Set

Control

The

L05HD has two microprocessors, The Hercules located on the Family board and the

TV Controller located on the Trident board.

The Hercules, 7200, provides control for the entire set. During standby, the

Hercules and the Remote sensor are powered by the 3.3 volt supply. The customer

communicates with the Hercules via the Remote sensor and Power switch located

on the Front Control panel. The power supplies are switched On via the

STBY-CONT and B lines. The TV Controller is reset by the C control line. The

I2C bus communicates with the EEPROM 7601, Tuner 1000, TV Controller 7206,

Trident 7201, A/D 7210, TV Display Processor, 7221, and HDMI panel.

Hercules Processor

Signal

flow

The

output of the Tuner is fed to the SAW filter, 1002, and then to 7200, Hercules,

on Pins 104 and 105. The SVHS (YC) signals are combined inside 7200. IC 7200

selects between AV1, AV2, Side, and Tuner composite video. The selected

composite video is output on Pin 65. Video buffered by Transistor 7211 is fed

to IC 7206 located on the Trident panel which extracts Closed Caption text and

Teletext information. This IC also generates the OSD (On Screen Display). Video

buffered by 7212 is fed to the Trident IC which has an internal 3-D Comb Filter

and A/D converter. IC 7201 rescales the picture to 1080i.

Component video is inserted into the YPbPr input located on the Family board.

The HDMI panel converts the HDMI signal into an analog YPbPr format. Both of

these signals are fed to the Switch, 7205 which selects between the two. The

selected signal is fed to IC 7210 which performs an A/D conversion. This 24 bit

signal is fed to 7201. The Scaler (Trident IC) converts the signal to a 1080i

format as well as performing picture enhancement functions.

DRAM ICs 7215, 7216, 7217, and 7218 stores picture data for the Scaler as it is

being processed. And internal D/A conversion circuit outputs the 1080i signal

is an RGB format on Pins 27, 28 and 29. Horizontal and Vertical sync is output

on Pins 34 and 35.

The

RGB signal from the Scaler is fed to the TV Display Processor, 7221. RGB is

output from this IC to the CRT panel. Horizontal and Vertical drive is output

to the Family board.

TV Display Processor

IC 7221 is used in a large number of Philips chassis for a long period of time.

RGB in inserted in Pins 30, 31, and 32. This signals are converted to a YUV

format before being fed to the Color level control. RGB from 7206 is inserted

on Pins 35, 36, 37, and 38. The signal then goes to a Brightness and Controls

control circuit. RGB to the CRT panel is output on Pins 40, 41, and 42. During

warm up, a cathode calibration signal is fed to the CRT panel on the RGB lines.

This signal is then fed back to CRT panel.

RGB

is fed to the CRT panel on connector 1331. The CRT panel for the L05HD has a

single chip CRT drive circuit. RGB is fed to 7330 on Pins 1, 2, and 3. Signal

is output to the CRT on Pins 7, 8, and 9. BC_INFO or Cutoff on Pin 5 is fed

back to the TV Signal Processor on the Trident panel. The IC is powered by a

200 volt supply on Pin 6.

DC operating voltages for the CRT panel are located on connector 1351. The

Filament voltage is located on Pin 2. The 200VA voltage on Pin 5 powers 7330.

The VBAT voltage on Pin 3 and the +12V_LOT voltage on Pin 6 powers the SVM

circuit.

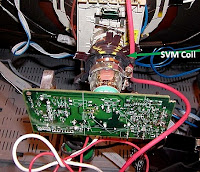

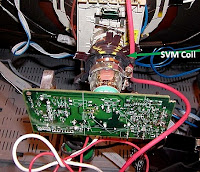

SVM

There

are two coils on the deflection coil in addition to the Vertical and Horizontal

winding. The SCAVEM coil (Scan Velocity

Modulation) sharpens the edges between light and dark transitions.

The SVM_ROT signal drives both the SCAVEM and the Rotation coil. The SCAVEM

circuit is powered by the Vbatt and +12V_LOT supplies. Capacitor 2376 blocks

the dc Rotation signal to prevent it from entering the SCAVEM circuit.

Capacitor 2381 blocks the higher frequency SCAVEM signal to prevent it from

affecting the Rotation drive.

SVM coil and rotation circuit

Audio

All

audio processing and control is performed by the Hercules IC 7200 located on

the main board.

Audio is included in the HDMI bit-stream. Digital audio from 7002 is fed to IC

7011, Audio DAC. Audio from 7011 is fed to IC 7050, switch, which has only one

input since the second input is not used in the HD version. The output of 7050

is fed to the Hercules IC located on the Main board. Audio for the CVI input

should be inserted into AV1. Audio is output from the Hercules on Pins 68 and

69 to the Audio Amplifier, IC 7990. This is a two channel 20 watt amplifier.

Audio

output

Main audio is output on Pins 68 and 69 and fed to the audio amplifier 7990. The

audio amplifier is a dual 10 watt amplifier. It is powered by the +VAUDIO and

-VAUDIO supplies. These are +16 and -16 volts. To mute the amplifier, the

VOL_MUTE line goes Low switching transistor 7992 Off switching transistor 7991

On. The output of the amplifier is fed to the Side Jack panel.

Monitor audio is output on Pins 66 and 67 of 7200. These outputs are muted by

the STBY_CONT and POWER DOWN lines. The POWER DOWN line is High during normal

operation. As the set powers off, this line goes Low, switching 7993 Off.

Transistor 7104 then switches On to mute the output. The STBY_CONT line goes

High when the set is turned Off turning 7994 On, muting the output. Capacitor

2999 delays the turn-on of 7993 to prevent a pop in the speaker at set turn ON.