Sharp 32LS400, 36LS400, CL32S40,

CL36S40 Color Televisions How to enter the service mode, service adjustments

detail, full schematic

Used

ICs: M24C01B, IX3256CE [System control], STRF6626 [SMPS drive], TA8427 [Vertical scan output], Upc358C [Side PIN cushion control], F0035ME or F0039ME [HORIZONTAL OUT

TRANSFORMER], D2500 [Horizontal scan output transistor], CXA2074 [M.T.S], TC90A45F

[COMB FILTER], AN5285K [Sound control], IX11235CE [Audio output], IX3253CE

[PIF,SIF,Chroma, Video, Deflection jungle]

POWER

INPUT..................................................... 120V AC 60 Hz

POWER RATING

32L-S400, CL32S40 ..........................................................

140W

36L-S400, CL36S40 ..........................................................

165W

PICTURE SIZE

32L-S400, CL32S40 ................................ 3,073cm2 (476sq inch)

36L-S400, CL36S40 ................................ 3,905cm2 (605sq inch)

CONVERGENCE .............................................................

Magnetic

SWEEP DEFLECTION .....................................................Magnetic

FOCUS ................................................Hi-Bi-Potential

Electrostatic

Service

work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and the servicing guidelines

HIGH VOLTAGE CHECK

High voltage is not adjustable but

must be checked to verify that the receiver is operating within safe and

efficient design limitations as specified checks should be as follows:

1. Connect an accurate high voltage meter between ground and anode

of picture tube.

2. Operate receiver for at least 15 minutes at 120V AC line voltage, with a

strong air signal or a properly tuned in test signal.

3. Enter the service mode and select the service adjustment "S19" and Bus data

"01" (Y-mute on).

4. The voltage should be approximately 32.8kV(32LS400,

CL32S40)/33.4kV(36L-S400, CL36S40) (at zero beam).

If a correct reading cannot be obtained, check circuitry for malfunctioning

components. After the voltage test, make Y-mute off to the normal mode.

X-RADIATION PROTECTOR CIRCUIT TEST

1) Apply 120V AC using a variac transformer for accurate input

voltage.

2) Allow for warm up and adjust all customer controls for normal picture and

sound.

3) Receive a good local channel.

4) Connect a digital voltmeter to TP653 and make sure that the voltmeter reads

13.8 ±0.7V (32L-S400, CL32S40)/13.2 ± 0.7V(36L-S400, CL36S40).

5) Apply external 17.0V DC (32L-S400, CL32S40)/16.2V DC (36L-S400, CL36S40) at

TP653 by using an external DC supply, TV must shut off.

6) To reset the protector, unplug the AC cord and plug the AC cord power ON.

Now make sure that normal picture appears on the screen.

7) If the operation of the horizontal oscillator does not stop in step 5, the

circuit must be repaired before the set is returned to the customer.

Service mode

For adjustments of this model, the bus

data is converted to various analog signals by the D/A converter circuit.

[There are still a few analog

adjustments in this series such as focus and master screen voltage. Follow the

steps below whenever the service adjustment is required.]

Service mode

Before putting unit into the

service mode, check that customer adjustments are in the normal mode. Use the

reset function in the video adjustment menu to ensure customer controls are in

their proper (reset) position.

Service number selection

Once in the service mode,

press the Ch-up or Ch-down button on the remote controller or at the set.

The service adjustment number will vary in increments

of one, from "S01" to "P07". Select the item you wish to

adjust.

Data number selection

Press the Vol-up or down

button to adjust the data number.

To enter the service mode and exit service mode.

While pressing the Vol-up and Ch-up buttons at the same time,

plug the AC cord into a wall socket.

Now the TV set is switched on and enters the service mode.

To exit the service mode, turn the television off by pressing the power button.

Service mode display

and default set values

VCO Adjustment

1. Connect a digital voltmeter between pin (44) of IC201 and

ground.

2. Receive a good local channel.

3. Enter the service mode and select the service adjustment "S10".

4. Adjust the data so that digital voltmeter reads 2.2V.

5. Adjustment is completed, remove the voltmeter, return to "normal"

mode.

RF AGC Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service adjustment "S08".

3. Set the data value to point where no noise or beat appears.

4. Select another channel to confirm that no noise or beat appears.

Note 1 : You will have to come

out of the service mode to select another channel.

Note 2 : Setting the data to

"00" will produce a black raster.

Screen Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service adjustment "S03" and

set the data value to "00" to set the color level to minimum. (Record

original data code under adjustment "S03" before changing) You may

skip this step, if you selected a B/W picture or monoscope pattern.

3. Select the service adjustment "S19" and adjust the data value to

"01", this turn off the luminance signal (Y-mute).

4. Select the service adjustment "S04" and adjust data value to

"4B".

5. Adjust the master screen control until the raster darkens to the point where

raster is barely seen.

6. Adjust the service adjustments "S11" red, "S12" green and

"S13" blue to obtain a good grey scale with normal whites at low

brightness level.

7. Select the service adjustment "S19" and reset data to

"00". Select the service adjustment "S03" and reset data to

obtain normal color level.

8. Reset the master screen control to obtain normal brightness range.

White Balance Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service adjustment "S03" and

set to "00" (minimum color)(Record original data code under

adjustment "S03" before

changing). "S03" does not have to be adjusted, if you selected a B/W

picture or monoscope pattern.

3. Alternately adjust the service adjustment data of "S14" and

"S15" until a good grey scale with normal whites is obtained.

4. Select the service adjustment "S03" and adjust data to obtain

normal color level.

Sub-Picture Adjustment

1. Receive a good local channel.

2. Make sure the customer picture control is set to maximum.

3. Enter the service mode and select the service adjustment "S01".

4. Adjust the data value to achieve normal contrast range.

Sub-Tint Adjustment

1. Receive a good local channel.

2. Set customer tint control to center of it's range.

3. Enter the service mode and select the service adjustment "S02".

4. Adjust "S02" data value to obtain normal flesh tones.

Sub-Color Adjustment

1. Receive a good local channel.

2. Make sure the customer color control is set to center position .

3. Enter the service mode and select service adjustment "S03".

4. Adjust "S03" data value to obtain normal color level.

Sub-Brightness Adjustment

1. Receive a good local channel.

2. Make sure the customer brightness control is set to center position.

3. Enter the service mode and select the service adjustment "S04".

4. Adjust "S04" data value to obtain normal brightness level.

Vertical-Size and Linearity Adjustments

1. Receive a good local channel.

2. Enter the service mode and select the service adjustment "S09".

3. While observing the top and bottom of the screen, adjust "S09"

data value to proper vertical size.

4. Using the R502 control adjust for the best linearity.

Vertical Phase Adjustment

1. Enter the service mode and select the service adjustment

"S06".

2. Adjust data value to "00".

Note: This must be set

"00" when changed data retrace line will appear.

3.58MHz Trap Adjustment

1. Receive a good local channel.

2. Enter the service mode and select the service adjustment "S16".

3. This is a two position adjustment, "00" is ON, "01" is OFF.

4. Adjust data value to "01" for normal viewing.

Sharpness and Audio Balance Adjustments

1. Receive a good local channel.

2. Enter the service mode and select the service adjustments "S05"

for sharpness and "S17" for audio balance.

Sharpness

adjustment

3.

Adjust data value to "24"(center of data range) for sharpness

adjustment.

Audio balance adjustment

4. Adjust data value to "20"(center of data range) for Audio

balance adjustment.

Vertical Center Adjustment

1. Receive a good CATV channel.

2. Adjust the S502 so that the picture is centered.

Side Pincushion Adjustment

1. Receive a good CATV channel or crosshatch pattern signal.

2. Adjust the R676 so that the outermost line on the screen is straight.

Horizontal Size Adjustment

1. Receive a good CATV channel or crosshatch pattern signal.

2. Adjust the R678 so that the best horizontal size.

Energy save offset Adjustment

1. Enter the service mode and select the service adjustment

"S20".

2. Adjust data value to "23".

Note : This position is used to

preset the level for the energy save function.

Other Adjustments

1. Enter the service mode.

2. Adjust the following data values as listed below.

MTS ADJUSTMENT

MTS Level Adjustment

1.

Feed the following monaural signal to pin (14) of IC3001.

Monaural signal : 300Hz, 245mVrms

2. Connect the rms voltmeter to pin (39) of IC3001.

3. Enter the service mode and select the service adjustment "M01".

4. Adjust the data so that the rms voltmeter reads. Spec : 490 ±10mVrms.

MTS VCO Adjustment

1.

Keep the unit in no-signal state.

2. Connect the frequency counter to pin (39) of IC3001.

3. Connect a capacitor (100µF, 50V) in between positive(+) side of C3005 and

ground.

4. Enter the service mode and select the service adjustment "M02"

5. Adjust the data so that the frequency counter reads.Spec : 62.94 ±0.75kHz.

Filter Adjustment

1.

Feed the following stereo pilot signal to pin (14) of IC3001 .

Stereo pilot signal: 9.4kHz, 600mVrms.

2. Enter the service mode and select the service adjustment "M03".

3. Adjust the data until "OK" appears in position on the screen. Make

sure the "OK" is displayed almost at the center of the data range.

Separation Adjustment

1.

Connect the rms voltmeter to pin (39) of IC3001.

2. Receive the following composite stereo signal 1.

Composite stereo signal: 30% modulation, left channel only, noise reduction on,

300Hz

3. Enter the service mode and select the service adjustment "M04".

4. Adjust the data until the AC voltage reading of the RMS voltmeter is

minimum.

5. Receive the following composite stereo signal 2.

Stereo signal: 30% modulation, left channel only, noise reduction on, 3kHz

6. Enter the service mode and select the service adjustment "M05".

7. Adjust the data until the AC voltage reading of the RMS voltmeter is

minimum.

8. Take the above steps 1 thru 8 again for fine adjustment.

P-IN-P ADJUSTMENT [Picture in Picture]

P-IN-P Y LEVEL Adjustment

1.

Receive a good local channel.

2. Enter the service mode and select the service adjustment "P01".

3. Adjust "P01" data value to obtain normal contrast level

P-IN-P TINT Adjustment

1.

Receive a good local channel.

2. Enter the service mode and select the service adjustment "P02".

3. Adjust data value to "29".

P-IN-P COLOR Adjustment

1.

Receive a good local channel.

2. Make sure the customer color control is set to center position.

3. Enter the service mode and select service adjustment "P03".

4. Adjust "P03" data value to obtain normal color level.

P-IN-P Y-OFF SET Adjustment

1.

Receive a good local channel.

2. Enter the service mode and select the service adjustment "P04".

3. Adjust data value to "09".

P-IN-P Horizontal-position Adjustment

1.

Receive a good local channel.

2. Enter the service mode and select the service adjustment "P05".

3. Adjust data value to "0A".

P-IN-P BURST GATE PULSE (for MAIN)

1.

Receive a good local channel.

2. Enter the service mode and select the service adjustment "P06".

3. Adjust data value to "00".

P-IN-P FREE RUN

1.

Receive a good local channel.

2. Enter the service mode and select service adjustment "P07".

3. Adjust data value to "0B".

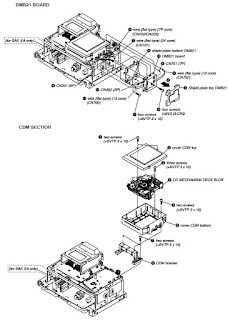

Block diagram

WAVEFORMS

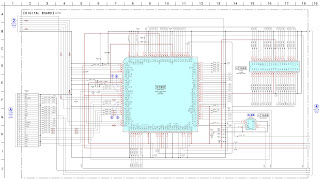

MODELS 32L-S400, CL32S40 SCHEMATIC

DIAGRAM: MAIN-1 Unit

MODELS 32L-S400, CL32S40 SCHEMATIC

DIAGRAM: MAIN-2 Unit

MODELS 36L-S400, CL36S40 SCHEMATIC

DIAGRAM: MAIN-1 Unit

MODELS 36L-S400, CL36S40 SCHEMATIC

DIAGRAM: MAIN-2 Unit

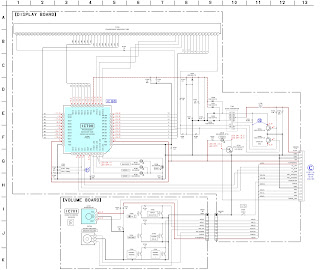

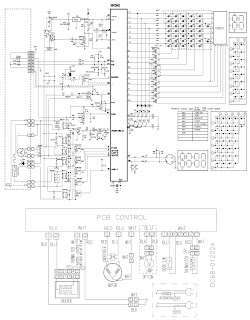

SCHEMATIC DIAGRAM: CRT Unit

SCHEMATIC DIAGRAM: P-IN-P Unit &

Control unit