No sound, LED blinking, standby ON/OFF,

No signal. Service menu settings – Vestel 17IPS62, Vestel MB82S

AUDIO AMPLIFIER-TAS5721 (optional)

The TAS5721 is a 15-W

stereo or 2x10 W + 1x15 W2.1 device, efficient, digital audio-power amplifier

for driving stereo bridge-tied speakers. One serial data input allows processing

of up to two discrete audio channels and seamless integration to most

digital audio processors and MPEG decoders. The device accepts a wide range of

input data and data rates. A fully programmable data path routes these

channels to the internal speaker drivers. The TAS5721 is a slave-only device

receiving all clocks from external sources. The TAS5721 operates with a PWM

carrier between a 384-kHz switching rate and a 352-KHz switching rate, depending

on the input sample rate. Oversampling combined with a fourth- order noise

shaper provides a flat noise floor and excellent dynamic range from 20 Hz to 20

kHz.

Audio Input-Output

–

15Wx2 into 8Ω

– Supports Single Device 0.1, 2.0, 2.1 Modes

– Wide PVDD Range, From 4.5 V to 26 V Performance

– Efficient Class-D Operation Eliminates Need for Heatsinks

– Requires Only 3.3 V and PVDD

– One Serial Audio Input (Two Audio Channels)

– I2C Address Selection via PIN (Chip Select)

– Supports 8-kHz to 48-kHz Sample Rate (LJ/RJ/I2S)

– External Headphone-Amplifier Shutdown Signal

– Integrated CAP‐Free Headphone Amplifier

– Stereo Headphone (Stereo 2‐V RMS Line Driver) Outputs

• Audio/PWM Processing

– Independent Channel Volume Controls With The 24-dB to Mute

– Separate Dynamic Range Control for Satellite and Sub Channels

– 21 Programmable Biquads for Speaker EQ

– Programmable Coefficients for DRC Filters

– DC Blocking Filters

– Support for 3D Effects

• General Features

– Serial Control Interface Operational Without MCLK

– Factory-Trimmed Internal Oscillator for Automatic Rate Detection

– Surface Mount, 48-Pin, 7-mm × 7-mm HTQFP Package

– Thermal and Short-Circuit Protection

POWER STAGE

The DC voltages required

at various parts of the chassis and panel are provided by a main power supply

unit. MB82S chassis can operate with PW05, IPS60, IPS70, IPS16, IPS17, IPS19, PW25,

PW26, PW82-3, PW03, PW04, PW06, PW07 as main power supply and also with 12V

adaptor.

Which power board can be used for board

to board or cable connection?

Board to board (BTB) : PW05, IPS60, IPS70, IPS16, IPS17, IPS19

Power Cable : PW25, PW26,

PW82-3, PW03, PW04, PW06, PW07

The power supplies generate 24V, 12V, 5V, 3,3V and 12V, 5V, 3.3V stand by mode

DC voltages. Power stage which is on-chassis generates 5V, 3V3 stand by voltage

and 12V, 8V, 5V, 3V3, 2.5V, 1,8V and 1,2V supplies for other different parts of

the chassis.

For PW26 and PW27 just common blocks are

enough for proper operation.

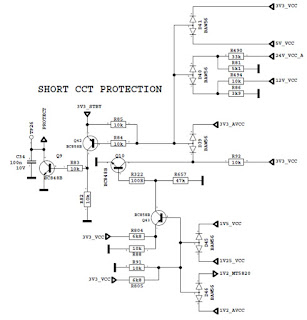

Short CCT Protection Circuit

Short circuit protection is necessary for protecting chassis and main IC

against damages when any Vcc supply shorts to ground. Protect pin should be

logic high while normal operation. When there is a short circuit protect pin

should be logic low. After any short detection, SW forces LEDs on LED card to

blink.

Panel Supply Switch Circuit

This

switch is used to open and close panel supply of TCON. It is controlled by port

of main u-controller. Also with this circuit panel sequence could be adjusted

correctly. 3 panel supplies are connected to this circuit. All of them are

optional according to panels.

SERVICE MENU

SETTINGS

In order to reach

service menu, First Press “MENU” Then press the remote control code

two times, which is “4725”.

In first screen following items can be

seen (MB8x is same as MB6x service menu):

USB Operations

USB

operations option can not be used directly. It can be used for updating panel

tool, hw configuration etc.

SOFTWARE UPDATE

In MB82 project

there is only one software. From following steps software update procedure can be seen:

1. MB82.bin directly inside of a flash

memory (not in a folder).

2. Put flash memory to the TV when TV is powered off.

3. Power ON the and OK button on

the remote control when the TV is opened.

4. If First Time Installation screen

comes, it means software update procedure is successful.

TROUBLESHOOTING: No Backlight Problem

Problem:

If TV is working, led is normal and there is no picture and backlight on the

panel.

Possible causes: Backlight pin, dimming pin, backlight supply, stby on/off pin

Backlight pin should be high in open position. If it is low, please check Q30

and panel cables.

Dimming pin should be high

or square wave in open position. If it is low, please check S16 for Mstar side

and panel or power cables, connectors.

Backlight power supply

should be in panel specs. Please check CN4 for MB82, related connectors for

power supply cards.

CI Module Problem

Problem:

CI is not working when CI module inserted.

Possible causes: Supply, supply control pin, detect pins, mechanical positions

of pins CI supply should be 5V when CI module inserted. If it is not 5V please

check CI-POWER-CTRL, this pin should be low.

Please check mechanical

positions of CI module.

Detect ports should be low. If it is not low please check CI connector pins, CI

module pins and 3V3-VCC on MB82.

Led Blinking Problem

Problem:

LED blinking, no other operation

This problem indicates a short on Vcc voltages. Protect pin should be logic

high while normal operation. When there is a short circuit protect pin will be

logic low. If you detect logic low on protect pin, unplug the TV set and measure the control voltage points with a multimeter to find the shorted voltage to ground.

No Sound Problem

Problem:

No audio at main TV speaker outputs.

Check supply voltages of VDD-AUDIO, 5V-VCC or 12V-VCC with a voltage-meter.

There may be a problem in headphone connector or headphone detect circuit (when

headphone is connected, speakers are automatically muted). Measure voltage at

HP-DETECT pin, it should be 3.3v.

No Sound Problem at Headphone

Problem:

No audio at headphone output.

Check HP detect pin, when headphone is. Check 5V-VCC and 3V3-VCC with a

voltage meter.

Standby On/Off Problem

Device cannot boot, TV hangs in standby mode.

There may be a problem about power supply. Check 12V-VCC, 5V-VCC and 3V3-VCC

with a voltage-meter. Also there may be a problem about SW. Try to update TV

with latest SW. Additionally it is good to check SW printouts via

hyper-terminal (or Tera term). These printouts may give a clue about the

problem.

No Signal Problem

Problem:

No signal in TV mode.

Check tuner supply voltage; 3V3-TUN. Check tuner options are correctly set in

Service menu. Check AGC voltage at IF-AGC pin of tuner.

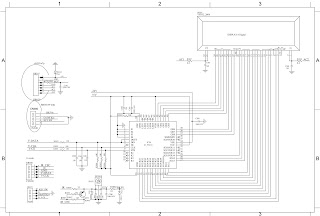

Schematic diagram