3D

phonic, radio data system, MP3-WMA-WAV-MPEG-3 ASF PLAYBACK – Digital Direct

Progressive Scan

Output

Power: 120 W (60 W + 60 W) at 6Ω (10%

THD

Speaker

units:

Tweeter: 4 cm cone × 1

Woofer: 12 cm

cone × 1

Impedance: 6Ω

Disassembly

procedure

Main body

Removing the Metal

cover

(See Fig.1 and

2)

(1) Remove the

four screws A (both side) attaching the Metal cover. (See Fig.1)

(2) Remove the

two screws B attaching the Rear cover. (See Fig.2)

(3) Remove the

five screws C attaching the Metal cover. (See Fig.2)

Removing the

Front panel assembly

(See Fig.3 to

5)

(1) Disconnect

the card wire from the FL board assembly connected to connector CN205 of the Micon

board assembly. (See Fig.3)

(2) Remove the

two screws D attaching the Front panel assembly. (See Fig.4)

(3) Disengage

the hook a (Fig.4) and hook b (Fig.5) from the bottom chassis. (See Fig.4, 5)

Removing

the Fan

(See Fig.6, 7)

(1) Disconnect

the connector wire from the Fan connected to connector CN602 of the Audio board

assembly. (See Fig.6)

(2) Remove the

two screws E attaching the Fan. (See Fig.7)

Removing the Tuner pack

(See Fig.7, 8)

(1) Disconnect

the card wire from the Tuner pack connected to connector CN11 of the Micon

board assembly. (See Fig.8)

(2) Remove the

two screws F attaching the Tuner pack. (See Fig.7)

Removing

the Audio board assembly

(See Fig.9 to

11)

(1) Disconnect

the connector wire from the Power transformer connected to connector CN601 of

the Audio board assembly. (See Fig.9)

(2) Disconnect

the card wire from the USB jack board assembly connected to connector CN811 of

the Audio board assembly. (See Fig.9)

(3) Disconnect

the card wire from the Audio board assembly connected to connector CN203 of the

Micon board assembly. (See Fig.9)

(4) Disconnect

the card wire from Micon board assembly connected to connector CN217 of the

Audio board assembly. (See Fig.9)

(5) Disconnect

the card wire from DVD mechanism assembly connected to connector CN722 of the

Audio board assembly. (See Fig.9)

(6) Disconnect

the card wire from USB jack board assembly connected to connector CN810 of the

Audio board assembly. (See Fig.9)

(7) Disconnect

the card wire from Micon board assembly connected to connector CN219 and CN220

of the Audio board assembly. (See Fig.9)

(8) Remove the

two screws G attaching the Audio board assembly. (See Fig.9)

(9) Remove the

two screws H attaching the Power amplifier IC. (See Fig.10)

(10) Remove

the three screws J attaching the Amplifier board assembly. (See Fig.11)

Removing

the Micon board assembly

(See Fig.12,

13)

(1) Disconnect

the connector wire from Power transformer connected to connector CN202 of the

Micon board assembly. (See Fig.12)

(2) Disconnect

the card wire from Power trans board assembly connected to connector CN201 of

the Micon board assembly. (See Fig.12)

(3) Disconnect

the card wire from DVD mechanism assembly connected to connector CN21, CN711

and CN831 of the Micon board assembly. (See Fig.12)

(4) Disconnect

the card wire from the USB jack board assembly connected to connector CN206 of

the Micon board assembly. (See Fig,12)

(5) Remove the

two screws K attaching the Micon board assembly. (See Fig.12)

(6) Remove the

four screws L attaching the Micon board assembly. (See Fig.13)

Removing

the DVD mechanism assembly

(See Fig.14 to

16)

(1) Remove the

two screws M (both side) attaching the bracket. (See Fig.14)

(2) Disconnect

the connector wire from DVD mechanism assembly connected to connector CN803 of

the USB jack board assembly. (See Fig.15)

(3) Remove the

one screw N attaching the DVD mechanism assembly. (See Fig.16)

Removing

the USB jack board assembly

(See Fig.17)

Remove the one

screw P attaching the USB jack board assembly.

Removing

the Power transformer board assembly

(See Fig.18 to

20)

(1) Remove the

one screw Q attaching the Power trans board assembly. (See Fig.18)

(2) Remove the

one screw R attaching the Power trans board assembly. (See Fig.19)

(3) Disconnect

the connector wire from Power cord connected to connector CN101 and disconnect

the connector wire from Power transformer connected to connector CN102 of

the Power

trans board assembly. (See Fig.20)

Removing

the FL board assembly

(See Fig.21)

(1) Remove the

five screws S attaching the FL board assembly.

3.1.11

Removing the Key board assembly

(See Fig.21)

(1) Remove the

Volume knob.

(2) Remove the

six screws T attaching the Key board assembly.

(3) Disengage

the six hooks c engaged Key board assembly.

DVD

mechanism. Removing the traverse

mechanism

(See Fig.1 to

6)

(1) Remove the

two screws A attaching the tramecha holder from top side of DVD mechanism

assembly. (See Fig.1)

(2) Remove the

two screws B attaching the DVD module board. (See Fig.2)

(3) Remove the

four screws C attaching the CB holder and take out it. (See Fig.3)

(4) Remove the

four screws D attaching the traverse mechanism. (See Fig.4)

(5) Solder the

solder part of DVD pick up. (See Fig.5)

(6) Disconnect

the card wire from CN101 and CN201 on the DVD module board. (See Fig. 6)

Caution:

• Solder the

short land section on the DVD pickup before disconnecting the card wire from

the connector on the DVD pickup. If the card wire is disconnected without

attaching solders, the pickup may be destroyed by static electricity. • When

attaching the DVD pickup, be sure to remove solders from the short land section

after connecting the card wire to the connector on the DVD pickup.

Removing

the pickup assembly

(See Fig.7 to

11)

(1) Remove the

two rod springs pressing the guide shaft. (SeeFig.7)

(2) Remove the

screw E and F attaching the spring holder. (See Fig.8)

(3) Remove the

read screw from traverse mechanism assembly. (See Fig.9)

Caution:

When remove

the lead screw, do not loss the middle gear. (See Fig.10 and 11)

(4) Remove the

bar spring pressing the shaft. (See Fig.10)

(5) Take out

the pickup assembly from traverse mechanism chassis by order. (See Fig.11)

Removing

the feed motor assembly

(See Fig.12)

(1) Remove the

one screw G attaching the feed motor assembly.

(2) Remove the

feed motor wires from solder part of spindle motor board.

Removing the

spindle motor assembly

(See Fig.13)

Remove the two

screws H attaching the spindle motor from spindle motor board.

Removing

the tray assembly

(See Fig.14

& 15)

(1) Remove the

two screws J attaching the clamper base. (See Fig.14)

(2) Remove the

one screw K attaching the shaft guide from bottom side. (See Fig.14)

(3) Remove the

two screws L attaching the shaft guide from top side. (See Fig.15)

Caution:

When attach

the tray assembly, boss of loading sub assembly should attach to guide of

bottom side at tray assembly. (See Fig.15)

ADJUSTMENTS

Attention in

service of DVD section

(1) When

pickup, Flash ROM, DVD module board were changed, initialize EEPROM by all

means.

(2) When full

initialization was executed, execute learning with a DVD test disk by all

means.

Test disc :

VT-501, VT-502

Learning

method: It is adjusted automatically by normal playback of a DVD test disc.

DVD

test mode

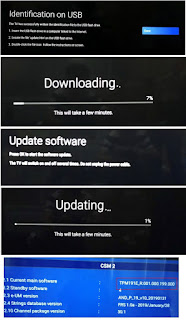

TO

ENTER DVD TEST MODE, TO EXIT DVD TEST MODE

(1) During

TEST MODE (except for Device Key write & DVD Region Re-write), press POWER

key.

(2) To exit

TEST MODE for Device Key Write & DVD Region Re-write, first AC OFF, then AC

ON again to return to normal state.

DVD

MODULE EEPROM INITIALIZATION, DEVICE KEY CHECKSUM DISPLAY

DVD

CHECK MODES

(1) AC Power

OFF.

(2) Press and

hold DVD/CD + keys on the front panel. Then AC power ON while holding these

keys.

(3) DVD

mechanism will start in TEST MODE. The following will be display on the set.

xx =

Destination information as follows; JC/1U/D/E/2U/3U/UB/UT/4U/UY/EE/UF

y = region

number

v = study

state information from MECHA-CON

w =

initialization state from MECHA-CON

TO

EXIT DVD TEST MODE

(1) During

TEST MODE (except for Device Key write & DVD Region Re-write), press POWER

key.

(2) To exit

TEST MODE for Device Key Write & DVD Region Re-write, first AC OFF, then AC

ON again to return to normal state.

DVD

MODULE EEPROM INITIALIZATION

DEVICE

KEY CHECKSUM DISPLAY

(1) During

TEST MODE, press MENU key on remote control to enter DEVICE KEY CHECKSUM

display for DVD-AUDIO (CPPM).

(2) System

will display as follows.

(3) Press MENU

again to enter DEVICE KEY CHECKSUM display for DVD-VR MODE (CPRM).

(4) System

will display as follows.