FUNAI 32" COLOR LCD TELEVISION - LCD-A3206 - LCD-B3206 - LCD-C3206 - LCD-D3206

Hot Chassis Warning

a. Some

TV receiver chassis are electrically connected directly to one conductor of the

AC power cord and maybe safety-serviced without an isolation transformer only

if the AC power plug is inserted so that the chassis is connected to the ground

side of the AC power source. To confirm that the AC power plug is inserted

correctly, with an AC voltmeter, measure between the chassis and a known earth

ground. If a voltage reading in excess of 1.0V is obtained, remove and reinsert

the AC power plug in the opposite polarity and again measure the voltage

potential between the chassis and a known ground.

b. Some TV

receiver chassis normally have 85V AC(RMS) between chassis and earth ground regardless

of the AC plug polarity. This chassis can be safety-serviced only with an

isolation transformer inserted in the power line between the receiver and the

AC power source, for both personnel and test equipment

protection.

c. Some TV

receiver chassis have a secondary ground system in addition to the main chassis

ground. This secondary ground system is not isolated from the AC power line.

The two ground systems are electrically separated by insulation material that

must not be defeated or altered.

Disassembly Flowchart

This

flowchart indicates the disassembly steps for the cabinet parts, and the CBA in

order to gain access to item(s) to be serviced. When reassembling, follow the steps

in reverse order. Bend, route and dress the cables as they were.

Disassembly Method

HOW TO INITIALIZE THE LCD TELEVISION

To

put the program back at the factory-default, initialize the LCD television as

the following procedure.

How to initialize.

1. Turn the power off.

2. To enter the service mode, while pressing [SETUP]

button, press [STANDBY-ON] button on the TV unit.

- To cancel the service mode, press [STANDBYON] button on the remote control.

3. To initialize the LCD television, press “DISPLAY” button on the remote

control unit.

4. Confirm "FF" indication on the upper left of the screen.

ELECTRICAL ADJUSTMENTs

Electrical adjustments are

required after replacing circuit components and certain mechanical parts. It is

important to perform these adjustments only after all repairs and replacements

have been completed.

Also, do not attempt these adjustments unless the proper equipment is

available.

Test Equipment Required

1.

DC Voltmeter

2. Pattern Generator

3. Colour Analyzer

How to Set up the Service mode.

1.

Turn the power off.

2. While pressing [SETUP] button, press [STANDBYON] button on the TV unit.

- To cancel the service mode, press [STANDBY-ON] button on the TV unit.

Initial Setting

General

Enter

the Service mode.

Set the each initial data as shown on table.

Flicker Adjustment

This

adjustment is needed when reparing T-CON CBA.

1. Enter the Service mode.

2. Press [2] button on the remote control unit. The following screen appears.

3. If Flicker Adjustment

is not fit, the screen become the following.

4. Turn the VR1 on the LCD

Module so that flash stops.

Purity Check Mode

This

mode cycles through full-screen displays of red, green, blue, and white to

check for non-active pixels.

1. Enter the Service mode.

2. Each time pressing [7] button on the service remote control unit, the

display changes as follows.

Auto Calibration.

Purpose: To bring the colour adjustment of each component into standard

alignment.

Symptom of Maladjustment:

If this adjustment is incorrect, component signals do not reproduce the corresponding color.

Gain

Adjustment

1. Input white raster signal (5%=5 IRE, 100%=100 IRE) from Component jack.

2. Enter the service mode.

3. To enter the Auto Calibration. adjustment mode, press [5] button on the

service remote control unit.

4. To start auto adjustment, press [CH UP] button on the service remote control

unit.

- In the auto adjustment mode, “Please Wait” appears on the screen.

- Upon completion, “OK” and appears on the screen.

- If the auto adjustment failure, “ NG” appears on the screen.

Offset Adjustment.

5. Input white raster signal (5%=5 IRE) from Component jack.

6. Enter the service mode.

7. To enter the Auto Calibration adjustment mode, press [6] button on the

service remote control unit.

8. To start auto adjustment, press [CH UP] button on the service remote control

unit.

- In the auto adjustment mode, “Please Wait” appears on the screen.

- Upon completion, “OK” and appears on the screen.

- If the auto adjustment failure, “ NG” appears on the screen.

The following adjustment normally is not attempted

in the field. Only when replacing the LCD Panel then adjust as a preparation.

White Balance Adjustment

*This

adjustment is needed when repairing T-CON CBA.

Purpose: To mix red, green and

blue beams correctly for pure white.

Symptom of Maladjustment: White

becomes bluish or reddish.

1. Operate the unit for more

than 20 minutes.

2. Input the White Purity.

3. Set the color analyzer

to the CHROMA mode and bring the optical receptor to the center on the LCD-Panel

surface after zero point calibration as shown.

Note: The optical receptor must

be set perpendicularly to the LCD Panel surface.

4. [CVBS]

Enter the Service mode. Press “VOL DN” button on the remote control unit

and select “C/D/S 1” mode.

[YUV]

Enter

the Service mode. Press “VOL DN” button on the remote control unit and select

“C/D/S 2” mode.

[RGB]

Enter the Service mode. Press “VOL DN” button on the remote control unit

and select “C/D/S 3” mode.

5. [CVBS]----(APL 70%)

Press “6” button to select “DB 1(C/D/S 1)” for Blue adjustment. Press

“4” button to select “DR 1(C/D/S 1)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “DB 1(C/ D/S 1)” or “DR 1(C/D/S 1)”.

Refer to “1. Initial Setting.”

[CVBS]----(APL 25%)

Press “3” button to select “COB 1(C/D/S 1)” for Blue adjustment. Press

“1” button to select “COR 1(C/D/S 1)” for Red adjustment. When “x” value and

“y” value are not within specification, adjust “COB 1(C/D/S 1)” or “COR 1(C/D/S

1)”. Refer to “1. Initial Setting.”

After adjusting (APL 25%), verify (APL 70%) again and adjust repeatedly until

both values are within specification.

6. [YUV]----(APL 70%)

Press “6” button to select “DB 2(C/D/S 2)” for Blue adjustment. Press

“4” button to select “DR 2(C/D/S 2)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “DB 2(C/ D/S 2)” or “DR 2(C/D/S 2)”.

Refer to “1. Initial Setting.”

[YUV]----(APL 25%)

Press “3” button to select “COB 2(C/D/S 2)” for Blue adjustment. Press

“1” button to select “COR 2(C/D/S 2)” for Red adjustment. When “x” value and

“y” value are not within specification, adjust “COB 2(C/D/S 2)” or “COR 2(C/D/S

2)”. Refer to “1. Initial Setting.”

After adjusting (APL 25%), verify (APL 70%) again and adjust repeatedly until

both values are within specification.

7. [RGB]----(APL 70%)

Press “6” button to select “DB 3(C/D/S 3)” for Blue adjustment. Press

“4” button to select “DR 3(C/D/S 3)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “DB 3(C/ D/S 3)” or “DR 3(C/D/S 3)”.

Refer to “1. Initial Setting.”

[RGB]----(APL 25%)

Press “3” button to select “COB 3(C/D/S 3)” for Blue adjustment. Press “1”

button to select “COR 3(C/D/S 3)” for Red adjustment. When “x” value and “y”

value are not within specification, adjust “COB 3(C/D/S 3)” or “COR 3(C/D/S

3)”. Refer to “1. Initial Setting.”

After adjusting (APL 25%), verify (APL 70%) again and adjust repeatedly until

both values are within specification.

8. Turn the power off and on again. (Main power button on the TV unit.)

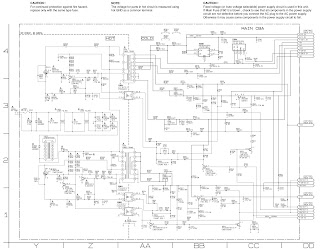

Power [SMPS] and

backlight board schematic.

No comments:

Post a Comment