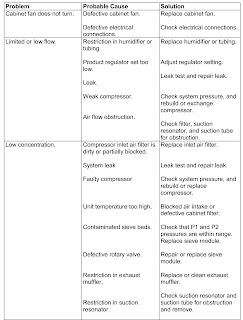

TROUBLESHOOTING

Before reviewing the troubleshooting chart, the following

steps may be useful to isolate any malfunctions:

Turn the concentrator on. If unit does not turn on, refer to

troubleshooting chart.

- Make sure all filters are clean.

- Turn flow meter completely open, up to the highest setting. The ball should rest at the top of the scale. If setting is not greater than 5.5 l/min, adjust regulator so that the ball level exceeds 5.5 l/min with the flow meter completely open.

- Connect test pressure gauge to the outlet fitting of the unit. The pressure should read approximately 7 psig (50 kPa).

- Connect test pressure gauge to the P1 test port on the air tank. The pressure should be cycling between approximately 16 and 34 psig (110 and 235 kPa).

- Make sure the unit is cycling properly by observing the pressure gauge cycle between a high and a low pressure. If the unit is not cycling properly, refer to troubleshooting chart.

- Make sure that the unit is leak free by testing all tubing connections and fittings with leak testing solution. Protect circuit board from solution and start leak test at the heat exchanger, following the air flow through the unit to the oxygen outlet. Repair all leaks by tightening connections and fittings.

- Set the concentrator at 5 l/min and connect pressure test gauge to P2 at the top of the sieve beds. Determine pressure parameters by observing high and low pressure points on the gauge. It should cycle between approximately 9 psig and 16 psig (62 to 110 kPa). If pressures are high or low, refer to the troubleshooting chart.

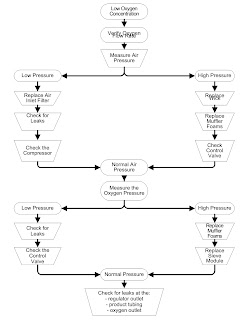

Review troubleshooting chart to isolate and repair any other

malfunctions. The following diagnostic

flow chart will help to isolate potential problems.

Click on pictures to Zoom. Click ß at the top left of

the browser, to come back.

Tool Kit and Pressure Test Gauge

The tools needed for you to properly service the Mark5 Nuvo

unit are listed below:

► Requires no special tools; generally available tools

including common pliers, channel lock, wire cutters, needle-nose pliers,

slotted-head screwdriver, long Phillips head screwdriver, 8-inch adjustable

wrench, 7/16-inch socket, 7/16-inch combination wrench, 5/8-inch combination

wrench and 3/8-inch combination wrench.

► For convenience, it is desirable to have a battery

operated drill motor available to remove and install screws.

► An accurate pressure test gauge to take both high and low

pressure readings on the Mark5 Nuvo unit should be kept available at all times.

This gauge connects to the pressure test ports on top of the air tank and on

top of the sieve bed.