DISPLAY CONFIGURATIONS

Three configurations of DLP projection systems are currently

being manufactured, differentiated by the number of chip, one, two, or three.

The HDLP50W151 uses a one chip configuration.

A simplified example

of a one-chip system.

The configuration choice depends on the intended market

application and is based on a trade off between light utilization efficiency,

brightness, power dissipation, lamp technology, weight, volume, and cost. The

single-chip projector is self-converged, lower in cost, and permits the very

lightest portable designs.

LIGHT ENGINE

The imager in the light engine is a single DLP device with

an array of 1280x720 (921,600) micro-mirrors.

Another part of the light engine is the color wheel that is used to sequentially display red, green, and blue images

on the imager. The light engine

contains a Driver circuit board that contains the TI chipset. Alignment information is stored in a EEPROM

located on the engine driver board. These alignments include color temperature

and color wheel index.

DLP LIGHT ENGINE

LAMP

Two cooling fans are located in the light engine, one for

the DMD device and one for UHP (Ultra High Pressure) lamp.

COLOUR WHEEL OPERATION

The color wheel contains 6 segments; 2 reds, 2 greens, and 2 blues and spins at a

rate of 120Hz. This means for every incoming 60Hz frame from the chassis, 12 color sub frames are displayed on the imager at a rate of

720Hz.

DLP LIGHT ENGINE

INPUTS TO LIGHT ENGINE

The inputs to the light engine include the Power Supplies

(+2.5V, +3.3V, +12V, +5V).

The Power_Good signal is an active high signal which

indicates that all of the supplies are at an acceptable level. This signal is used to give the engine an advance

warning that the supplies are going down in case of an AC loss. The Power Good

signal must go low a minimum of 1ms prior to the supplies dropping so that the

light engine processing circuitry can park the mirrors in a reliable state

prior to power loss. Another input is

the DVI encoded video from the formatter circuit. Control of the light engine

is accomplished via the I2C Run 2 data

bus from the DM2CR module.

COOLING FANS

The light engine driver board powers two cooling fans. The

DLP fan speed is varied depending on the temperature around the light

engine. The temperature is monitored by

the DM2CR by reading a temperature sensor via the I2C bus. Under normal conditions

the fan voltage should be about 8V but can rise to a maximum of 12V as the

temperature rises. Fan rotation is monitored by DM2CR. When a stopped or locked

fan is detected the DM2CR shuts down the instrument down and fan error codes

are logged.

LIGHT ENGINE START-UP

- The light engine takes approximately 10 seconds to power up and display a picture after the power button is pressed. It takes most of this time for the lamp to come up to full brightness.

- After Power supplies and the Power Good are up, the micro brings the DLP processing circuitry out of reset by writing to the light engine bus expander IC.

- Once the DLP processing circuitry is brought out of reset, The micro in the DLP processing circuitry begins initialization of the engine. The first step is to start the color wheel spinning up to an acceptable rate (720RPM).

- Once the DLP processing circuitry senses the wheel is spinning OK, it will then strike the lamp by activating the lamp_en signal to the ballast. The DDP1010 then waits to receive the User_Lamplit signal.

- The DM2CR microprocessor polls the bus expanding reading the Ballast_lamplit input pin. This signal comes from the ballast and indicates that the lamp has started successfully. When the micro detects this signal, it then “passes” it along to the DLP processing circuitry by outputting the User_Lamplit signal.

- When the DLP processing circuitry sees the User_Lamplit signal, it does a soft reset and is ready to receive I2C commands from the DM2CR and to display video.

DLP LIGHT ENGINE START-UP SEQUENCE

LAMP START-UP COOL DOWN

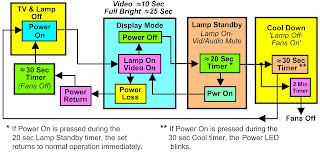

When the set is tuned off via the power button or remote,

the unit displays a blue screen and slowly dims the screen leaving the lamp and

power supplies on for about 20 seconds. During this 20 second interval the user

can turn the set back on immediately in case he inadvertently shut it off. After the 20 second interval, the lamp is turned

off but the run supplies and fans are left on for an additional 2 minutes to allow

for lamp cool down. After the lamp is turned off, the user will not be allowed to turn the set on for 30 seconds. If he tries to the power LED will flash which

indicates the lamp is in cool down mode.

UHP (Ultra High Pressure) lamps can be damaged during a “hot

strike” (when the lamp is turned on before it has had a chance to cool down

from the previous on time). Because of this issue the following sequence

is used is use to power up and shut down the lamp.

POWER ON

The UHP (Ultra High Pressure) lamp can be damaged or it’s life

span shortened by turning it on while hot (a hot strike). For this reason, multiple

protective measures have been taken in the form of multiple timers. When the Power button on the front panel or

the remote control is pressed, the TV & the Lamp turns on immediately.

DISPLAY MODE

Both the lamp and the video and audio are turned

on immediately when the power button is pressed. When the unit is powered on, video can be seen in approximately

10 seconds, however full brightness takes approximately 25-30 seconds due to lamp

warm-up time.

POWER RETURN

In the case of a power outage, when the power returns a 30 second

timer is activated. The unit will not turn back on before the 30 seconds have

timed out because the system doesn’t know if power was lost for 10 seconds or

10 minutes, therefore the system must ensure that the lamp has cooled before

turning on.

LAMP STANDBY

Whenever the unit is powered off, video is immediately

‘blanked’ but the lamp remains on. A 20 second timer is activated. This is done

in case the customer accidentally turned off the unit or has changed their

mind. If power on is pressed before the 20 second timer runs out, video is

immediately un-blanked.

LAMP COOL DOWN

After the standby timer expires (20 seconds), the lamp is

turned off and enters the Cool-Down mode.

When the lamp is turned off two timers are activated. The first is a 30

sec timer that prevents the instrument from being turned on until the cool-down

timer has expired. After 30 seconds, the unit can be powered up

again. If the Power On is pressed before the 30-second

cool down timer has expired, the Power LED blinks slowly. It’s important to

realize that this is normal and is done to protect the lamp. After the 30

seconds cool down timer expires the unit will start normally. The second is a two minute timer that keeps

the fans running to cool the lamp if the unit is left off.

When the set is tuned off via the power button or remote,

the unit displays a blue screen and slowly dims the screen leaving the lamp and

power supplies on

for about 20 seconds. During this 20 second interval

the user can turn the set back on immediately in-case he inadvertently shut it

off. After the 20 second interval, the lamp is turned off but the run supplies

and fans are left on for an additional 2 minutes to allow for lamp cool down.

After the lamp is turned off, the user will not be allowed to turn the set on

for 30 seconds. If he tries to the power LED will flash which indicates the

lamp is in cool down mode.