CALIBRATION

Authorized Welch Allyn personnel or agents must service the Atlas Monitor at 6 month intervals. Maintenance requirements are specified for 6 month and 12 month service intervals. The monthly CO2. Reset operation can be performed by the user.

Authorized Welch Allyn personnel or agents must service the Atlas Monitor at 6 month intervals. Maintenance requirements are specified for 6 month and 12 month service intervals. The monthly CO2. Reset operation can be performed by the user.

- Every 6 months: CO2Calibration.

- Every 12 months: BP calibration, CO2 reset, battery voltage calibration, printer adjustment, and temperature calibration. Complete functional test.

TOOLS REQUIRED FOR SERVICE Click on image to Enlarge

SETTING DATE & TIME

Check date and time before doing any

calibration. Set date and time if incorrect. Set time and date as follows:

- Turn Atlas on.

- Press CLOCK button next to power on button to check date and time. Use the far right SELECT button to scroll. Highlight the date or time that needs changed.

- Press the SET button to adjust date and time.

- Press CLOCK button to exit.

Pangea Communication Protocol

The Pangea Communication Protocol allows interaction

of the Atlas with the computer through the serial interface port. A prompt is

emitted at the computer screen when the instrument powers up and is ready to

accept commands. The prompt is Pangea>. A prompt is emitted after the

completion of each pangea command. Pangea commands are case sensitive. They are

in English only.

BP CALIBRATION

Required material.

- 500cc vessel 4.

- Squeeze bulb with one-way valve

- PC with HyperTerminal

- Calibrated digital manometer

- Tubing and T fittings

- Serial cable

- To start HyperTerminal you must have Windows7 95 or higher installed on your computer.

- From the Windows main screen follow the following sequence: Start => Programs => Accessories => Communication => HyperTerminal.

- HyperTerminal setting are: 9600 baud rate, 8 bit word, 1 stop bit no parity, no flow control ANSI character set.

- When you open HyperTerminal you will see a screen similar to the example in Figure. You will be prompted for a connection description. Choose any name. After you type in a name click OK.

- The next window you will see will be the window as shown. Click on Connect using then click on COM1.

- Set the port settings as shown in the example in Figure. Now click OK.

- Connect the pressure meter, bulb, and 500cc vessel to BP port with “T” connectors as shown below..

- Connect the Atlas to PC with serial cable.

- Turn the Atlas on. Start Hyper Terminal on PC. Press the <Enter> key and you should see a Pangea>prompt.

NOTE: Take no more than 3 minutes for the 50mmHg calibration

nor more than 3 minutes for the 250mmHg calibration as the Atlas will

automatically, as a safety feature, open the blood pressure valve. If this

happens you will have to turn the Atlas off then back on again and restart the

calibration again.

50mmHg Calibration

- Enter the following commands at the Pangea prompt.

Pangea> bp valve close<ENTER>

Pangea> bp safety off<ENTER>

Pangea> bp cal 5000 Do not press <ENTER> yet

- Raise the pressure with bulb to as close to 50.00mmHg as possible.Now press <ENTER>.

- Release the pressure.

250mmHg Calibration

- Enter the following command Pangea> bp cal 25000 Do not press <ENTER> yet

- Raise the pressure with bulb as close to 250.00 mmHgas possible. Now press < ENTER>

- Enter the following command to save the calibration in the Atlas. Pangea> nvram write<ENTER>

- Release the pressure.

CO2

Reset (623xx Models Only)

Required material.

- Watertrap

- Scrubber

NOTE: Make sure date and time are correct before performing

the CO2 reset.

- Turn Atlas on. Make sure the watertrap and scrubber are Non attached to the Atlas.

- Press the DATE/TIME button on the lower right of the monitor. The Set Date and Time and Other Options menu will be displayed.

- Press the CO2 /RESP ALARMS Off button. The CO2. Reset screen will appear.

- You will see the following messages on the CRT.

Reset”

“Install CO

2scrubber”

“Press Trend to abort”

- Install the watertrap to the Atlas. Install the scrubber to the watertrap.

- You will see the following instructions on the screen.

“May take up to five minutes” on CRT.

“Press Trend to abort” on CRT.

- After about 5 minutes you will see on the CRT.

Reset”

“Reset complete”

“Remove CO2

scrubber”

“Press the trend button to exit”

- Remove the CO2 watertrap and scrubber.

- Press TREND button to return to idle screen.

Replace watertrap after every six hours of use.

Treat watertrap and used CO2 sample lines as bio hazard material.

ET CO2 Calibration

Required material:

- Tank of approximately 10% CO2, balance N2 (certified) Blood Gas Mixture.

- Tubing and T connectors.

- Watertrap and scrubber.

- Make sure the watertrap and scrubber is not attached to the Atlas. Turn the Atlas on.

- Place the instrument into the Service Mode by pressing the DATE/TIME button. Make sure date and time are correct. Press the LEAD SELECT button.

- Press SELECT button and scroll down to Calibrate CO2.

- The message “Install CO2Scrubber” will appear on the right side of screen.

- Attach the scrubber to the water trap.

- Insert the scrubber/water trap assembly into water trap socket. The message. “Enter span gas value using Set button 10%” will appear.

- Press the SET button to change the value of span gas being used. The factory default value is 10%. Calibrate with a 8% to 12% certified CO2 concentration known to be ±0.01%).

- The message press “BP Start/Cancel” will appear at the bottom right of CRT. Press the BP/Start/Cancel button.

- If you receive a “Calibration Failed” message at this point, check the date. If date is 2022 or above it will fail CO2 calibration.

- Next you will see a message “Warming up”. After the Atlas warms up you will see a message “Attach CO2 gas”. Remove the scrubber from the CO2 water trap. Do not remove water trap.

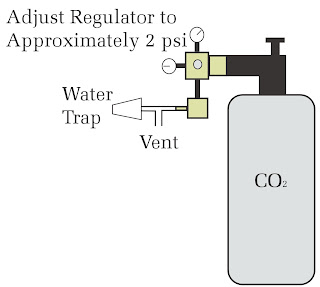

- Attach the certified source of CO2gas to the CO2 side-stream sampling tube as per Figure below.

- Adjust the CO2 regulator just enough to allow a small amount of gas to flow out of the vent (approximately 2 psi).

- Press the BP START/CANCEL button. The message: “Sampling” will appear on CRT. “CO2 calibration successful” or “CO2calibration failed” will appear on the CRT display.

- Press the TREND button to exit.

CAUTION: IMPROPER USE, STORAGE OR HANDLING OF COMPRESSED GAS

VESSELS CAN CAUSE DEATH ORINJURY. FOLLOW GAS MANUFACTURES SAFETY PROCEDURES.